Since 1911, Whirlpool has been innovating home appliances. For the past hundred-plus years, the world’s #1 major appliance company’s products shifted from basic devices to complex fusions of machinery, electronics and software. In some cases, like the modern washing machine, the products barely resemble their original iterations.

Constellation: The Star of Whirlpool’s Product Development

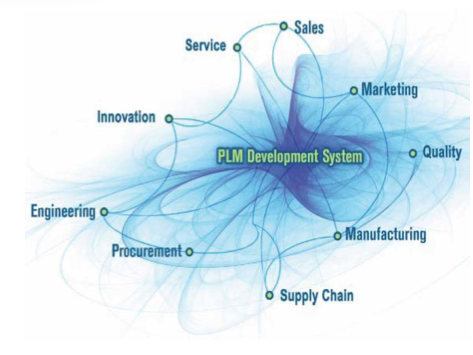

Whirlpool needed a product development process specifically devised for their design needs in order to remain competitive. The process they created, called Constellation, lays out an entire year’s Product Lifecycle Management (PLM) goals. Constellation is designed to:

- Shorten the length of Whirlpool’s product development cycles

- Increase consumer-related innovation

- Increase the number of product variations from a decreased number of platforms

- Improve cost and quality position of Whirlpool’s products

Their extensive list of products also requires PLM software that can supplement Constellation goals.

Whirlpool and PTC: Nearly Three Decades Strong

Since 1986, Whirlpool has used PTC’s design suite for its CAD solutions . The wide variety of PTC products include ProEngineer/Creo, Windchill ProjectLink, Windchill PDMLink, Windchill Quality Solutions, MathCAD, Integrity, PPMLink, Arbortext, Isodraw, and Product View.

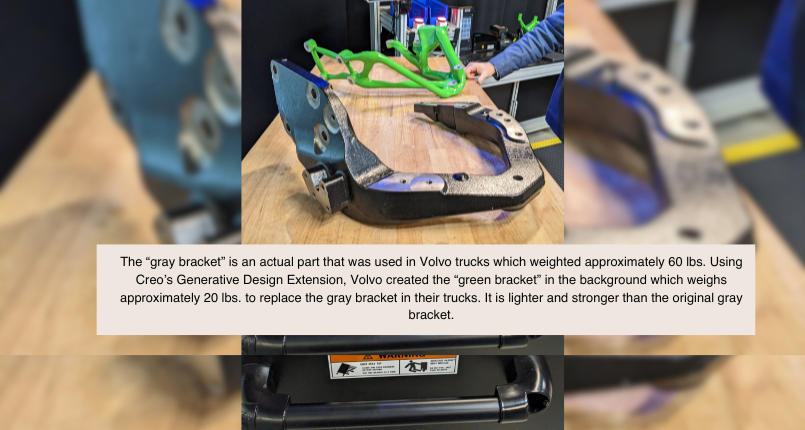

The Creo 2.0 suite and the Windchill suite play an essential role in helping Whirlpool manage its Application Lifecycle Management (ALM). One of its key features is its integration of parametric, direct, and organic subdivision shape modeling. It ensures Whirlpool doesn’t sacrifice speed for precision while editing complex designs. Windchill manages the entire process creating a coordinated and collaborative environment for the various teams in product development.

One of the key applications for Whirlpool in the Creo 2.0 suite is the Options Modeler. When used along with Windchill, it helps Whirlpool generate and validate precise 3D representations of product configurations. The Options Modeler also helps automate the creation of any Whirlpool product by defining common architecture and product modules, and managing how they interface and assemble.

PTC offers Whirlpool solutions to nearly all of their MCAD design and PLM needs. It’s an ideal partnership for both companies, with decades of history, and decades of innovation yet to come.