Do you know what a digital twin is? This term is critical to understanding how digital transformation affects design and engineering-driven organizations.

We all know what a human twin is: two siblings, born at almost the exact same time. Identical twins look exactly alike, and all twins share genetic material from their parents. Over time, the twins may encounter different life experiences, giving them their own unique style or appearance. Unlike digital twins, human twins are not forced to mirror experiences.

What are Digital Twins?

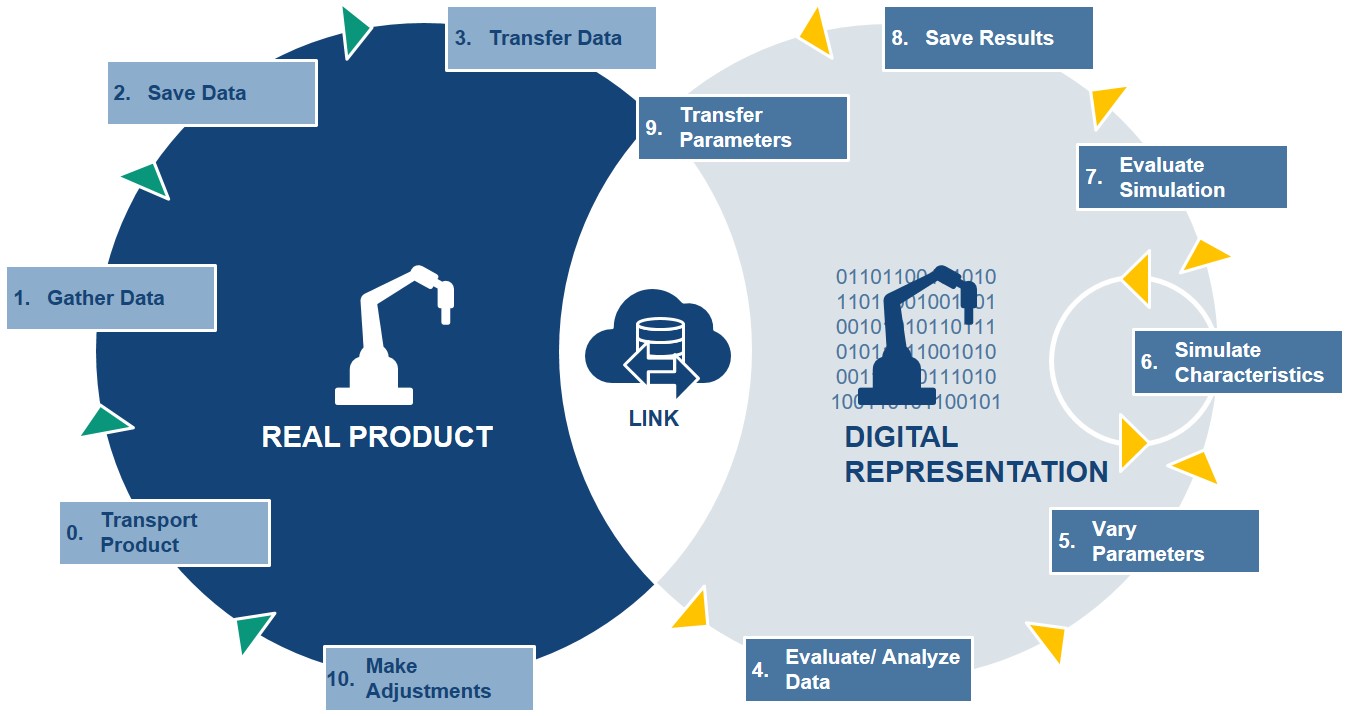

A digital twin is a virtual representation of a physical object that can understand and predict its physical counterparts. A digital twin has three components:

- a digital definition of its counterpart (generated from CAD, PLM, etc.)

- operational or experiential data of its counterpart (gathered from Internet of Things data, real-world telemetry, simulation, and beyond)

- an information model (dashboards, HMIs, and more) that correlates and presents the data to drive decision making

Digital twins can also capture varying forms and complexities of an object or experience. There are four main types of digital twins:

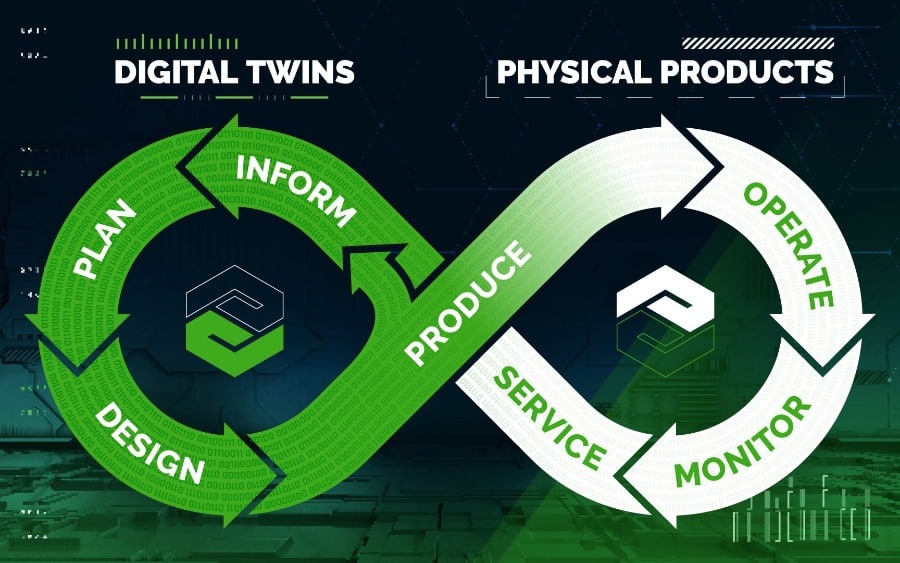

Product: This digital twin captures product lifecycle data from origin through the operating environment, right up to decommissioning. This enables product testing, performance evaluations, simulation, and more.

Process: Representations of complete manufacturing operations and production activities that deliver products or services. Process digital twins enable analysis of operations and logistics across design, production, supply chain, and more.

People: Delivers task information to workers, or captures data to improve process efficiency.

Places: Virtualize an entire place — a factory, a workstation, etc. — to see inside the complex workings of the environment. Engage with activity and analyze throughput.

You may not be aware, but most organizations are ready to use product-focused digital twins today! If you have CAD files, you have the groundworks for creating digital twins and leveraging this technology. Digital twins of process, people, and places require more sophisticated strategies. Spatial computing and analytics provide the basis for managing complex digital twins outside of your product.

Using Digital Twins in Practice

Remember, a digital twin is more than a simulation. It’s not a purely digital version of a product — there needs to be a physical counterpart. Think of it as a virtual representation of your product being used by a customer. Once you capture experiential data, you can marry that data to the digital definition of the product — your CAD model — and gain insights from the digital twin.

Taking this data even further, organizations rely on sound data management and analysis capability to maximize their digital twin insights. PLM is critical to this piece of digital twin strategy. Finally, augmented reality and Internet of Things tools also play a role. IoT can make your data real-time through smart connected products, sensors, and other data-harvesting tools that connect to your product in the field. AR lets users overlay their digital twin to a physical counterpart, making the final connection between the digital and physical twins for hands-on use cases.

The Impact of Digital Twin Strategies

Like any digital transformation strategy, using digital twins requires some up-front investment of time and resources. However, tangible improvements will transform your business.

Operational Improvement: Digital twins improve the performance of the product itself, from design to manufacture and throughout the customer experience. Better products give you an edge in the market and build stronger customer experiences and loyalty.

Generational Improvement: After analyzing digital twins over time, organizations can build fundamentally stronger products and processes. Monitoring product performance metrics enables designers to add strength to strength or address weaknesses in future product development cycles, exceeding peak performance of the past and creating new breakthroughs.

If you are curious to learn more about digital twin strategies and how they might work for your organization, contact 3 HTi. We offer complimentary digital transformation evaluations and audits to identify projects that offer the greatest ROI for your company, whether your focus is engineering, manufacturing or service. Digital transformation can be complex and confusing — make sure you have an expert guide to plan your roadmap along with you.