The manufacturing world is talking a lot about digital transformation and Industry 4.0, and one of the cornerstones of these initiatives is manufacturing IoT. IoT for manufacturing is a game-changer for the industry. The ability to integrate sensors into manufacturing equipment and feed information in real or near-real-time provides measurable benefits like:

- Reduced downtime

- Improved quality

- Less scrap and rework

- Increased efficiency

- Better adherence to schedules

- More predictable ship dates

You can’t argue with technology that lowers costs and improves customer satisfaction, but because it’s new, many companies aren’t sure how to get started with IoT for manufacturing. The first step is to ensure that you have the right tools in your technology arsenal.

You Need the Right Tools and Roadmap for Manufacturing IoT Success

ThingWorx from PTC is an ideal tool for manufacturing IoT because it integrates real-time sensor data from production equipment with existing IT systems. ThingWorx was purpose-built for industrial companies and addresses a wide range of manufacturing use cases. Built with these intentions, it’s the simple and easy solution to getting started with IoT for manufacturing.

Building IoT solutions is difficult for many manufacturers because it requires venturing into unknown territory, but ThingWorx was designed specifically to address this barrier. ThingWorx removes technical barriers and emphasizes practical solutions that work in the real world to deliver value quickly.

The ThingWorx platform includes reusable, modular functionality that simplifies development and speeds up implementation by eliminating delays due to learning curves or trial and error tests. These building blocks include predefined configurations that can be easily customized using the included library of connectors, business logic, and UI elements. These building blocks can be used to:

- Connect disparate devices and applications to enable access to multiple data sources

- Build IIoT and AR solutions

- Analyze data for real-time insights, recommendations, and predictions

- Manage connected devices and processes to improve overall performance

Built-In Apps

Using ThingWorx Manufacturing Apps, users can see the status of key metrics on customizable dashboards.

- The ThingWorx Production Advisor provides real-time visibility into production status and critical KPIs. It provides visibility into operations with current and historical machine metrics, which can be integrated into your operational and business data sources. The ThingWorx Production Advisor enables rapid root-cause analysis of performance issues and improves communication between production and management.

- The ThingWorx Controls Advisor allows you to monitor devices and PLCs remotely to alert you of problems and enables remote troubleshooting. This capability enables faster resolution of problems, reduces unplanned downtime, and increases flexibility. You may even choose to implement this as a new product as a service offering for your customers.

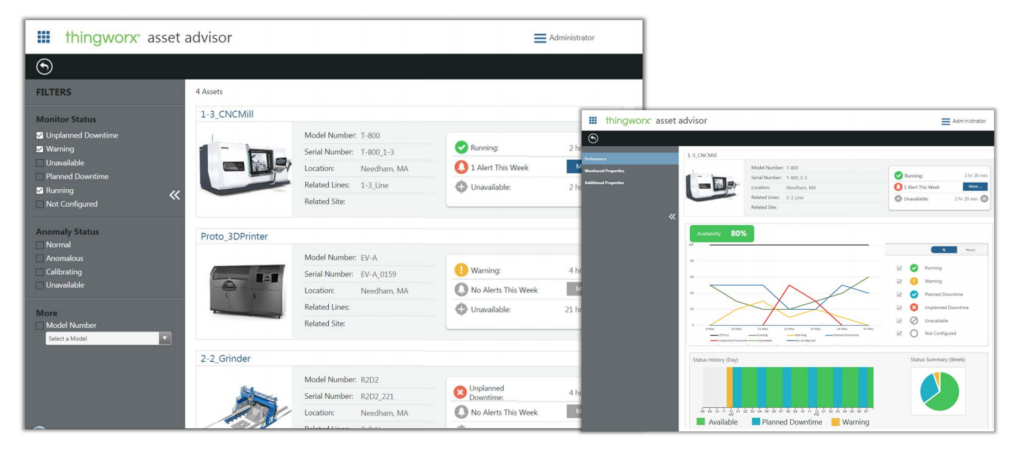

- The ThingWorx Asset Advisor allows you to plan repairs and preventive maintenance to minimize downtime with remote, real-time monitoring of assets and machinery. This improved visibility enables faster, more effective decisions and reduces scrap and rework to improve efficiency and quality.

Top Manufacturing IoT Use Cases

According to a McKinsey report published in 2019*, the top use cases for IoT for manufacturing include remote asset management, remote maintenance and service, predictive maintenance and asset management, and optimized equipment effectiveness. It’s no accident that these top manufacturing IoT use cases are specifically addressed out of the box with ThingWorx. PTC has been a trusted leader in the manufacturing industry since it was founded in 1985, and it has grown to over $1.26 billion in revenue by offering elegant and highly functional solutions to the most pressing manufacturing problems.

Enable Manufacturing IoT with ThingWorx

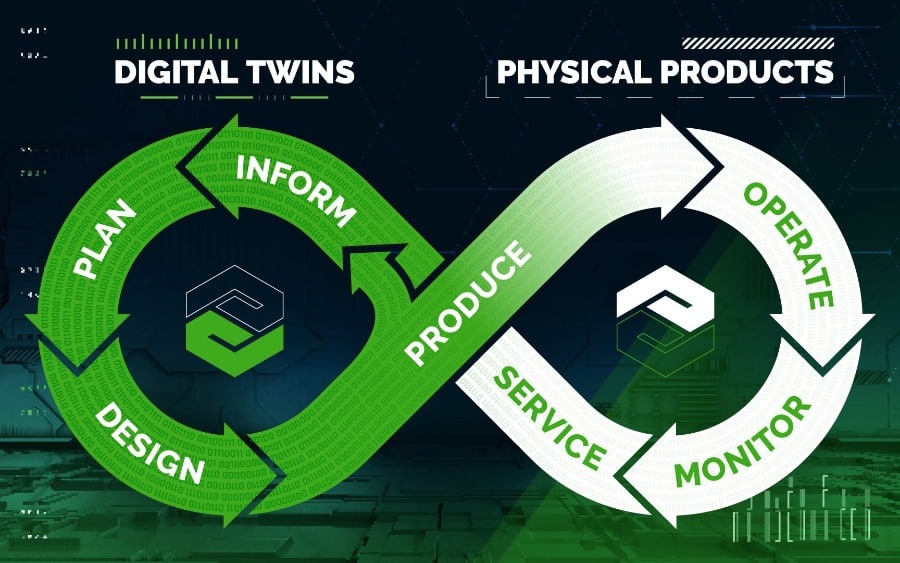

PTC ThingWorx gives you the power to easily connect devices across your entire manufacturing IoT landscape, to build customized IoT for manufacturing applications, to analyze the masses of data that manufacturing IoT generates, and to manage the data and the manufacturing IoT solutions and equipment to ensure low cost-efficient operations.

The power of IoT for manufacturing is in the ability to transform the connections and data to generate actionable insights across business functions and locations.

Why Not Go It Alone? It Takes More Than Software

When you decide it’s time to address IoT for manufacturing, one of the best decisions you can make is to work with a knowledgeable technology partner like 3HTi. We’ve been helping manufacturing companies since 2002, and we understand the factors that drive manufacturing. We are knowledgeable about the products we sell as well as the products we don’t, and we can explain why a product will meet your IoT for manufacturing requirements.

Sound good? Fill out the form below to discuss how IoT for manufacturing can help improve your operations.