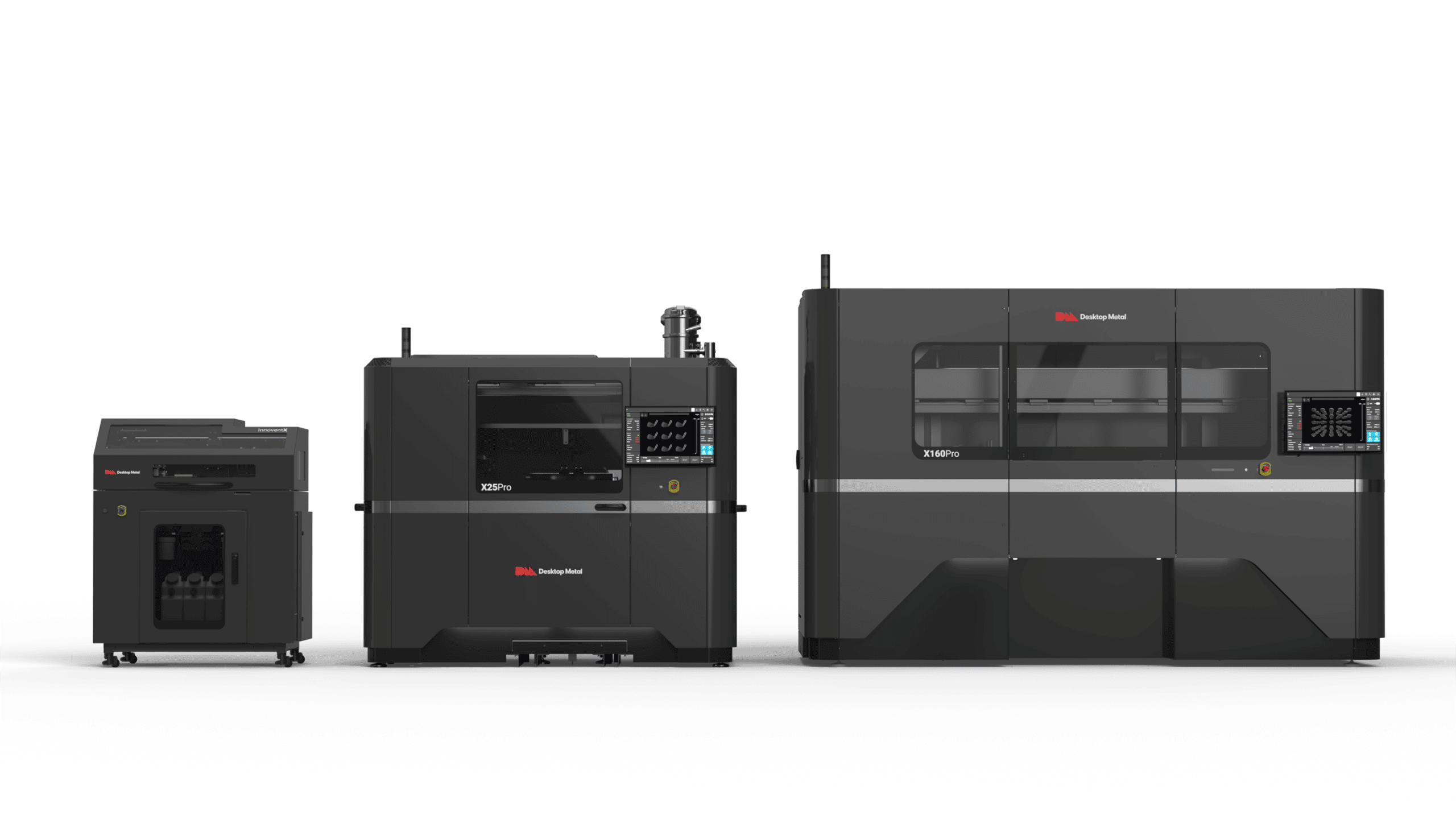

Innovent X

The most compact binder jet 3D printer for the production of metal, ceramic or composite parts. Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components.