It may be time to re-examine your current process for frontline worker training.

You may think your process is working well, but just as auto manufacturers didn’t recognize the money lost to inefficiency until the assembly line made it obvious, you may not realize that outdated instruction methods are leading to errors and costing you serious money.

Using Augmented Reality, or AR work instructions, you don’t have to overhaul your factory floor or take a risk implementing an unverified system—AR is already proven to succeed.

Studies show that AR work instructions help individuals remember processes better. Researchers observed that tasks such as assembly were conducted up to 80% faster, with zero errors.

Want to find out how Vuforia can support your manufacturing operations?

The Evolution of Digital Work Instructions

If you’re still relying on paper manuals and 3-ring binders, now is the perfect time to get on pace with 2021 and catch up to your competitors. If your materials are digitized, you’re on the right track. Digital work instructions make learning new tasks easier, from quickly finding the topic you need, to understanding a process with audio and video aids.

But digital work instructions alone can only get you so far. If you want to eliminate errors and capitalize on your company’s decades of knowledge, it’s time to adopt AR work instructions.

For optimal training efficiency, aim for a mix of digital work instructions (to convey theory and classroom knowledge) and AR capabilities (to deliver actionable, hands-on instruction).

How is AR Used to Collect and Disseminate Knowledge?

Implementing AR work instructions is a 3-step process:

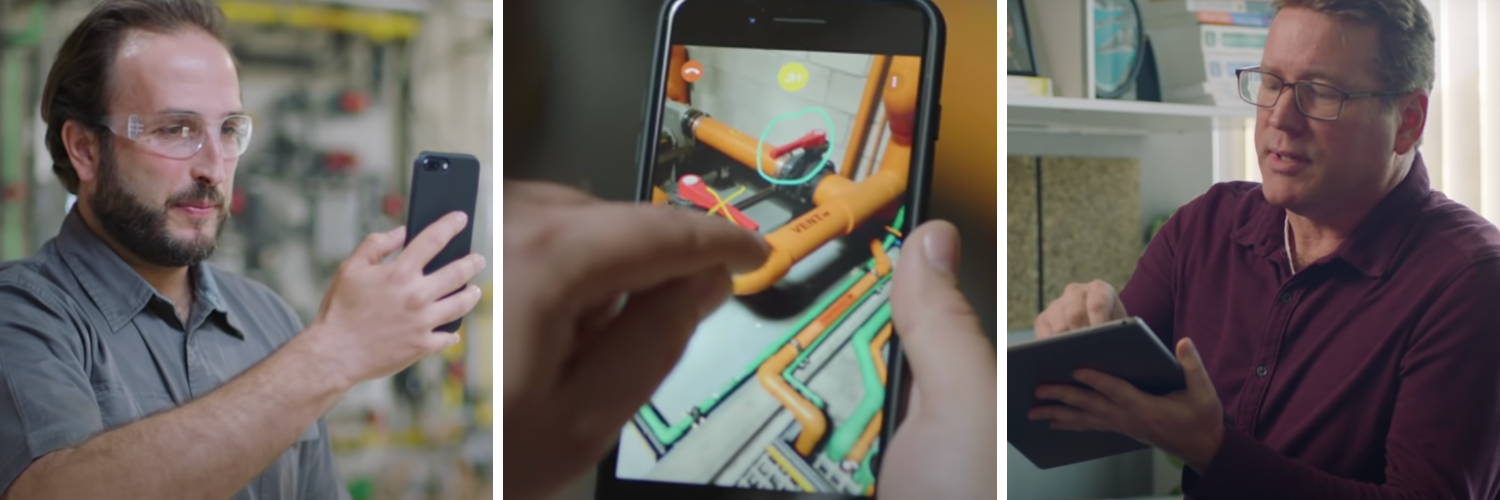

- One of your own experts records step-by-step instructions using a headset or eyewear device, performing actions on the same equipment your workers use, in the space they use it.

- The video is edited (and text and external digital files can be added) to create a user-friendly tutorial.

- The instructions are pushed out to frontline workers who then use eyewear (or hand-held) devices that display the tutorial in front of them, on the same equipment, as they perform the task.

Why are AR Work Instructions Superior?

AR work instructions do what digitization alone cannot:

Optimize your experts’ time. Complex processes are captured in just one recording, then that knowledge can be distributed countless times over.

Transform tutorials. No time is lost as workers follow along in real-time, advancing through steps via free-space gestures or voice commands, reviewing steps as needed.

Prevent costly errors. Interactions performed in a hybrid world are cemented into memory, and better retention means fewer mistakes—and a safer environment for everyone.

Close knowledge gaps—and that revolving door. AR provides the interactive experience the incoming labor force craves, filling your skills gap faster. Plus, if employees actually enjoy training and it helps them perform better, they’ll stick around for the long haul.

Is AR Right for My Company?

If you’re wondering if AR work instructions could benefit you, consider if any of the following scenarios apply to your company:

- Facing a skills gap as knowledge leaves with retirees

- Adhering to strict safety and compliance regulations

- Pushing for faster turnaround to meet customer demand

- Trying to offset expensive training costs

- A lack of quality, step-by-step procedures for work tasks

- An increase in product types and/or process complexity

- Experienced workers spending countless hours training newcomers

- Increasing the productivity of New Hires

- Reducing Employee churn

If any of these frustrations sound familiar, AR work instructions could be your solution.

A widening skills gap plus outdated instruction material is a deadly combination. AR work instructions address both of these challenges—and many others.

AR Work Instructions are a Breeze on the Vuforia Platform

If you’re interested in revitalizing your work instructions, don’t waste your investment on an unknown platform. Vuforia is the industry’s most advanced and widely adopted AR technology platform—and Vuforia Expert Capture is the fastest and easiest program on the market for creating AR work instructions. Expert Capture is so user-friendly, you can learn the program and create an instructional product for your workers in a matter of hours.

By using Vuforia Expert Capture, GlobalFoundries accelerated training time by 40% and decreased unscheduled downtime by 25%

And PTC Vuforia Expert Capture doesn’t stop with work instructions—a whole suite of AR-enabled software is available to optimize your factory floor:

And PTC Vuforia Expert Capture doesn’t stop with work instructions—a whole suite of AR-enabled software is available to optimize your factory floor:

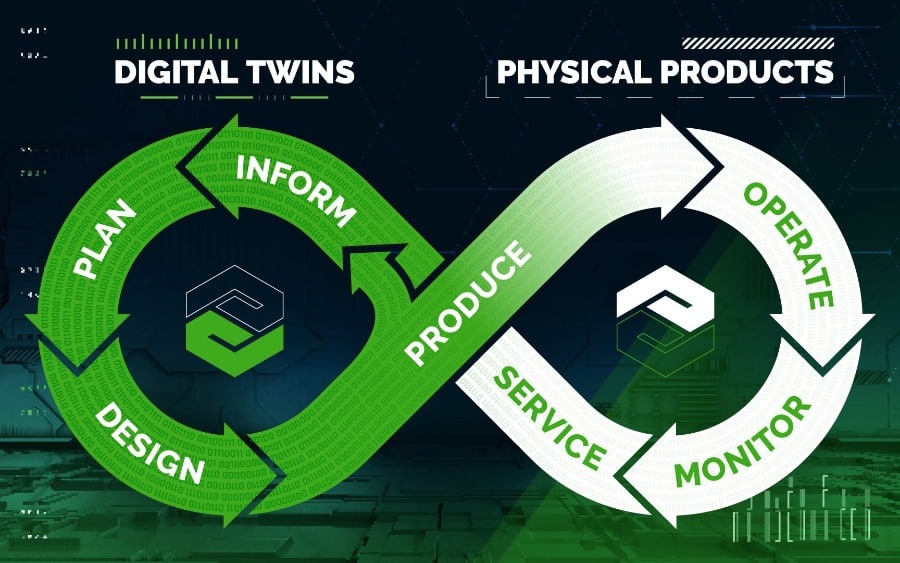

- Vuforia Studio: Transform CAD and IoT data into 3D visualizations on the factory floor.

- Vuforia Chalk: Provide expert remote assistance with environment sharing.

Take the Next Step in Your Digital Transformation

A McKinsey & Company study looked at companies who not only survive but thrive during crisis. Two commonalities stood out: cutting-edge technologies and the ability to fill talent gaps. If this isn’t a clear sign that value-added AR is a solid investment, we’re not sure what is!

Fill out the form below to how easy it is to capture the knowledge of your workforce using Vuforia Expert Capture.