Incomplete fill, undesirable weld line location, improper wall thickness are some of the most common molding issues which plastics part designers often encounter. Moldex3D eDesign Basic Package offers designers a powerful tool to quickly verify the part design for manufacturability so as to avoid the above-mentioned molding issues. Plastics designers can utilize the unique auto-meshing function to prepare the model for analysis in no time. Additionally, designers are able to obtain product insights in terms of the pressure required to fill the part, potential weld line and air trap locations, etc. Employing Moldex3D eDesign Basic Package upfront helps companies to design products without manufacturability issues, improve quality and efficiency, reduce development costs, and shorten time to market.

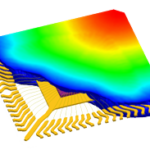

Automatic eDesign meshing technology for model preparation saves precious time

Automatic eDesign meshing technology for model preparation saves precious time- True 3D filling solver provides accuracy insights without requiring intensive CAE knowledge

- Results with figures and animations enhance communication

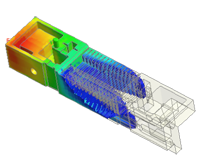

Verify wall thickness in the early design stage

Verify wall thickness in the early design stage

Basing on Moldex3D proprietary eDesign technology, every plastics part designers are able to prepare 3D mesh model easily with eDesign Basic. Users are able to quickly verify wall thickness for potential filling issues and improve their designs upfront. A built-in thickness modification tool allows users to directly and easily modify wall thickness without invoking the original CAD software.

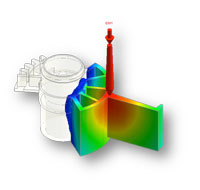

Analyze a part with complete runner system within few clicks

The gate wizard supports various kinds of gates and runner wizards guide you through steps of creating the entire melt delivery system. The pre-processor simplifies the model creation and allows designers to validate designs efficiently with the high-performance true 3D Flow solver.

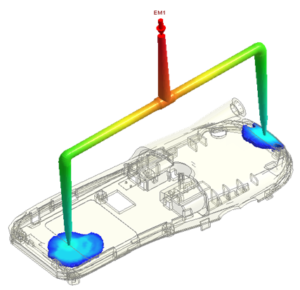

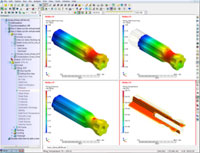

Generate reports automatically and present results in multiple ways

Generate reports automatically and present results in multiple ways

Post-processing tools enable users to demonstrate molding process and product properties with real-time contours, graphs and animation. From the automatic report generator, you benefit on quick reports and efficient communication. Moldex3D brings you confidence in your design and helps you in successful decision making.

What’s Inside Moldex3D eDesign Basic

| FlowMoldex3D Flow enables users to simulate the filling patterns of injection molding to help predict potential manufacturing problems, such as weld lines, air traps, short shots, sink marks, etc., and verify gate contribution for flow balance. | |

| DesignerMoldex3D Designer, designers are able to verify and optimize design changes more effectively and more flexibly. | |

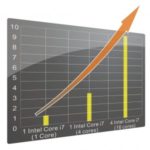

| Parallel Computingall Moldex3D 3D solvers support multi-core and multi-CPU parallel computing to greatly shorten simulation time. Parallel computing can be done locally at your desktop or remotely on a computing cluster. | |

| ViewerMoldex3D Viewer is a standalone and free tool that visualizes Moldex3D’s analysis results. It can generate reports automatically in HTML or PowerPoint format. With its extensive visualization capabilities, users can view pros and cons of all simulations and share identification with their teams, mold makers, engineers, executives, partners, and customers. | |

| Additional Solution OptionsRIM (Recommended for thermoset materials only)Modules from above package are also available in RIM Solution, which is designed for thermoset materials only. For more information about RIM solution, please see our Product Comparison Chart. Moldex3D RIM Solution is able to analyze the reactive injection molding process for thermoset materials. The typical applications include injection molding of unsaturated polyester, polyurethane, liquid silicon rubber, epoxy molding compound, etc. It is capable of simulating cavity filling and curing, part warpage, fiber orientation, multi-component process, etc. |

Automatic eDesign meshing technology for model preparation saves precious time

Automatic eDesign meshing technology for model preparation saves precious time Verify wall thickness in the early design stage

Verify wall thickness in the early design stage

Generate reports automatically and present results in multiple ways

Generate reports automatically and present results in multiple ways