Moldflow Analysis for Plastic Injection Molding

Moldflow Analysis for Plastic Injection Molding

The application of moldflow analysis in injection-molded plastic parts is now fundamental in part structural design and molding process optimization. Injection molding analysis is capable of simulating the filling, packing, and cooling processes as well as the part warpage after ejection.

Moldex3D is a leading CAE product for the plastic injection molding industry. With the best-in-class analysis technology, Moldex3D can help you simulate the widest range of injection molding processes to optimize product designs and manufacturability, shorten time-to-market, and maximize product ROI.

Moldex3D is a leading CAE product for the plastic injection molding industry. With the best-in-class analysis technology, Moldex3D can help you simulate the widest range of injection molding processes to optimize product designs and manufacturability, shorten time-to-market, and maximize product ROI.

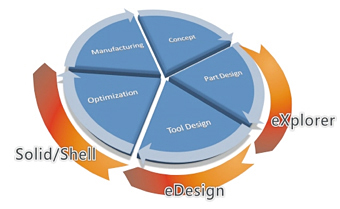

Moldex3D Products

- eXplorer is a CAD-embedded tool that allows CAD users to perform quick filling analysis for designing better plastic parts

- eDesign is suite of tools that helps you to simulate your part and mold designs before manufacturing begins

- Solid/Shell is a complete series of advanced engineering simulation tools for in-depth analysis and optimization of the most advanced molding processes.

- Viewer allows the CAE engineer who utilizes injection molding simulation software to share knowledge acquired from simulation results with his team members, including part designers, mold makers, or even customers.

- Stress Viewer permits the CAE engineer to observe the distribution of residual stress on transparent parts.

- Moldex3d Mesh is an advanced mesh generator for fast preparation of complex geometries for Finite Element Analysis (FEA) and Computer-Aided Engineering (CAE), and it also provides powerful CAD capabilities as well as diverse data file exchange.

Moldflow Analysis for Plastic Injection Molding

Moldflow Analysis for Plastic Injection Molding