Product Design Verification Software

Moldex3D/Solid is the world’s leading true 3D simulation solution for in-depth product design verification and troubleshooting with the best-in-class 3D technology based on solid hybrid mesh and High-Performance Finite Volume Method (HPFVM), Moldex3D/Solid allows you to quickly optimize product designs and predict manufacturability.

Moldex3D/Solid is the world’s leading true 3D simulation solution for in-depth product design verification and troubleshooting with the best-in-class 3D technology based on solid hybrid mesh and High-Performance Finite Volume Method (HPFVM), Moldex3D/Solid allows you to quickly optimize product designs and predict manufacturability.

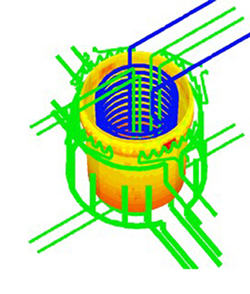

By using Moldex3D/Solid, users can perform true 3D simulation to the widest range of applications, including thick parts, parts that have extreme thickness changes from thin to thick, parts that are difficult to define a proper midplane model, or parts with very complicated geometry. Users can directly analyze the solid model without having to make significant model simplifications. The explicit analysis capabilities of Moldex3D/Solid provide users deep insight in solid plastic flow behavior from macro view to micro view, such as fountain flow, inertia effect, gravity effect or shear-induced viscous heating. The intuitive displays help users to evaluate analysis results in 3D and clearly address design defects.

Moldex3D/Solid has been proven by many users to be the most accurate 3D simulation solution on the market. It is capable of simulating the plastics filling and packing, mold cooling, fiber orientation and part warpage for thermoplastic injection molding. Additional modules simulate multi-component molding (MCM) and reactive injection molding (RIM).

Furthermore, Moldex3D/Solid has been developed with parallel computing technology in mind. With high-performance parallelized computing kernel, users can perform analyses on complex models in much less time.