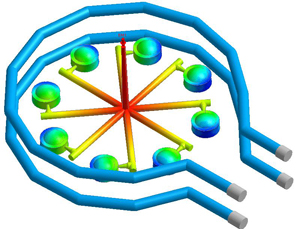

View Injection Molding Stress Areas

Don’t Let the Stress Block Your Success!

With increasingly shorter time-to-market, designers need to develop new products in the shortest time, and manufacturers have to significantly cut the process hours. Therefore, high injection speed and short cooling time become essential to improving productivity and competitiveness. For plastic parts, the exceeding injection speed or the uneven cooling could easily result in residual stress during injection. Residual stress would not only damage the strength of the products, but also bring difficulties in downstream processes. Only when we are clear on the causes, locations, and types of the residual stress in plastic parts, we can efficiently analyze and troubleshoot product designs and manufacturing processes.

With increasingly shorter time-to-market, designers need to develop new products in the shortest time, and manufacturers have to significantly cut the process hours. Therefore, high injection speed and short cooling time become essential to improving productivity and competitiveness. For plastic parts, the exceeding injection speed or the uneven cooling could easily result in residual stress during injection. Residual stress would not only damage the strength of the products, but also bring difficulties in downstream processes. Only when we are clear on the causes, locations, and types of the residual stress in plastic parts, we can efficiently analyze and troubleshoot product designs and manufacturing processes.

The simplest and quickest solution for above problems is Moldex3D Stress Viewer. With this tool, the distribution of residual stress on transparent parts can be directly observed. Consequently, improve the product quality, lower the costs and enhance the total competitiveness.

- Residual Stress Is Clear at A Glance

- Backlight Source Can Be Applied on Various Transparent Parts