Create designs faster with powerful, simple-to-use automation tools tailor-made for engineered-to-order custom products.

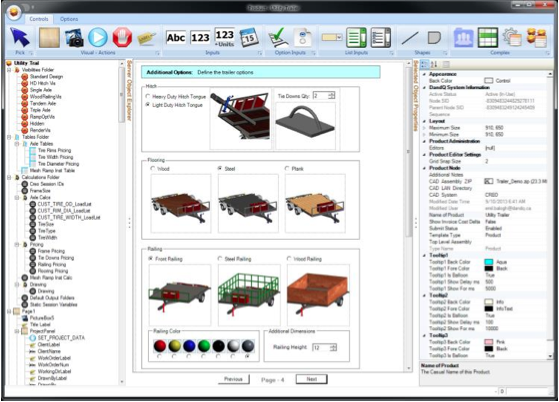

CONTROLS Pro Studio (CPS) is a Rapid Application Development software tool that bridges the gap between sales, design, engineering and manufacturing. The software integrates with PTC’s Pro/ENGINEER and Creo Parametric, Dassault Systèmes SolidWorks, and Autodesk Inventor.

CONTROLS Pro Studio allows users to quickly output quotes, orders and manufacturing plans for engineered-to-order products. It automates tasks that would normally be handled by design and engineering professionals, like making sure a product meets engineering, safety and design requirements. With CONTROLS Pro Studio’s CONTROL BASED DEFINITIONS (CBD), companies can minimize manual involvement, allowing engineers to focus on what they do best: innovating and producing new products.

Some of the software’s key capabilities and features include:

- Generate automated and interactive interfaces to drive the project, including design checks and rules for validity of the design

- Centralize business rules

- Generate automated configurations of parts and sub- assemblies for manufacturing using selected designs driven from the interactive interface

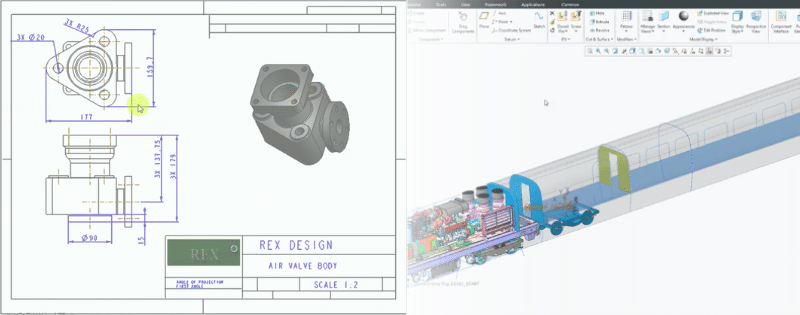

- Generate automated validated design information, including 3D/2D visuals, for each configuration run by the interactive interface

- Manage automatically all revisions and all engineering data and quotes in secure vaulting system

Deploying Controls Pro Studio helps engineering and design companies in the following areas:

- Application Engineering – Use Sales input to engineer a product solution within the boundaries of the competency of the manufacturer

- Cost Estimating – Use the Process Plan with the company’s capacity standards within the ERP system to predict the cost of machine time and labor required to build the designed product

- Design Control – Track changes from the quoted configuration to ensure accurate invoicing and project history

- Design Engineering – Prepare a detailed geometric design of the engineered product solution with associated Bill of Materials data identifying all the raw materials and purchased components needed for production

- Manufacturing Engineering – Prepare a detailed Process Plan identifying all of the tooling, setup, fabrication, machining, welding, assembly, CNC programs, and testing operations required to produce the product

- Purchasing – Reference the Bill of Materials with the company’s cost standards maintained within the ERP system to get the cost of acquiring all components required to build the designed product

- Sales & Marketing – Manage customer contact, promote interest in a unique product, and collect detailed specifications you need to accurately engineer and price your customer’s request

- Technical Documentation – Generate professional sales visuals, quotation drawings, production drawings, and process instructions to win purchase orders and guide production activities

Interested in learning more about CONTROLS Pro Studio? Read more here. Or why not contact us?