The rush to digital transformation has spawned a whole new vocabulary that has not been well defined. One of the latest terms to emerge is the digital thread. If you’re wondering what it is and what it means for your manufacturing operations, read on.

Defining the Digital Thread

A digital thread is an integrated view of everything about an asset or product throughout its lifecycle. The digital thread unites information from all aspects of product design manufacturing processing and even post-sale services.

A digital thread is an integrated view of everything about an asset or product throughout its lifecycle. The digital thread unites information from all aspects of product design manufacturing processing and even post-sale services.

The goal of the digital thread is to reduce the time and cost of the design-to-product cycle, to improve quality and to provide better post-sale service and support.

A digital thread provides an integrated view of products in an effort to improve quality and provide better service and support.

Digital Thread and Industry 4.0

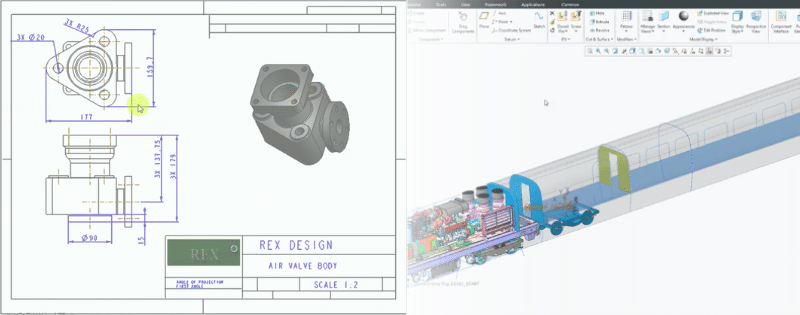

As companies begin their journey to Industry 4.0, they make be using 3D CAD tools such as Creo to create a digital twin for their products. The digital twin is a data-driven model that parallels the real-world operating characteristics of a product or process. A digital twin is an essential part of Industry 4.0 because it enables predictive maintenance and potential process problems.

The digital thread is the communication and conversation generated during the creation and operation of the digital twin.

According to NIST.gov (the National Institute of Standards and Technology agency), the digital thread is an important element in the emergence of Industry 4.0. The digital thread requires communicating product design ideas using 3D product models that enable production engineers to design and identify optimal manufacturing and quality activities. The manufacturing process information must be communicated back to design engineers for the inclusion of specifications for form, fit, function, inspection criteria and methods in 3D product models.

The digital thread is an important element in the emergence of Industry 4.0.

The ideal repository for capturing this ongoing communication is a 3D modeling system such as PTC Creo. PTC Creo includes options for 3D modeling of products and processes throughout the entire product lifecycle. Used with an IoT platform such as ThingWorx, the company has easily achieved the entire closed-loop digital twin/digital thread model necessary for achieving the benefits of Industry 4.0.

Benefits of the Digital Thread

Companies that adopt the digital thread concept will enjoy many benefits. The benefits accrue from improved communication across teams within the company’s own four walls as well as across the entire supply chain.

Topmost among the benefits of the digital thread are operational improvements. The manufacturing process will benefit from improved design for manufacturability. Manufacturability reduces manufacturing cycle time, eliminates or reduces production of scrap and defective units and helps to prevent unplanned downtime. As a result of these changes, the company experiences higher productivity, enhanced margins, and better customer satisfaction.

Improved operations beneficially impact all other processes throughout the organization like design, development, manufacturing, and more.

Better product designs help generate faster market acceptance and greater market share while improving profitability and customer satisfaction. In addition to operational enhancements and better overall product designs, companies will find that the digital thread enables:

- Better collaboration among departments and teams

- Reduced time to market

- Lower cost of design

- Higher quality products

- Improved manufacturability

- Decreased product cost

- Easier and more cost-effective maintenance, service and repairs

- Less unplanned downtime

- Increased margins

- Accessible platform for continuous improvement

- More satisfied customers

Adopting Digital Thread in Your Facility

The essence of the digital thread is the effortless enablement of communication and collaboration across the entire company, as well as with suppliers and even potential customers. Because this communication should be readily accessible and nearly instantaneous, the digital thread is not the place to try out home-grown solutions or complex integrations that simply add overhead to your existing processes.

The best solutions are designed to work together, such as 3D CAD and PLM products such as PTC Windchill or Creo, working with an Industry 4.0 ready tool such as ThingWorx, which has apps to support manufacturing, analysis and communication in IoT enabled plants.

Industry 4.0 is a complex undertaking with many moving parts and emerging technologies. Staying abreast of technology changes is challenging and complex, which is why it pays to work with an experienced and knowledgeable partner such as 3HTi.

If you would like to learn more about how 3HTi can help you launch your own digital thread capability, contact us today.