There are six basic components in traditional vacuum cleaners:

- An intake port, which may include a variety of cleaning accessories

- An exhaust port

- An electric motor

- A fan

- A porous bag

- A housing that contains all the other components

These pieces work together in a simple process: the electric motor powers the fan, which pushes air through the exhaust port. The airflow causes ambient air to rush into the vacuum through the intake port. The ambient air brings up debris from the ground and then deposits it in the bag.

Fantom Goes Next Level

The high-performance vacuum cleaners of Fantom, a manufacturer based in Turkey, take all this to the next level. They include highly specialized features in their designs, like:

- Roller brush systems that push debris out of carpet

- Automatically winding power cords

- Cyclonic separation systems

- Adjustable fan speed controls

- Various hoses and attachments

Design Challenges

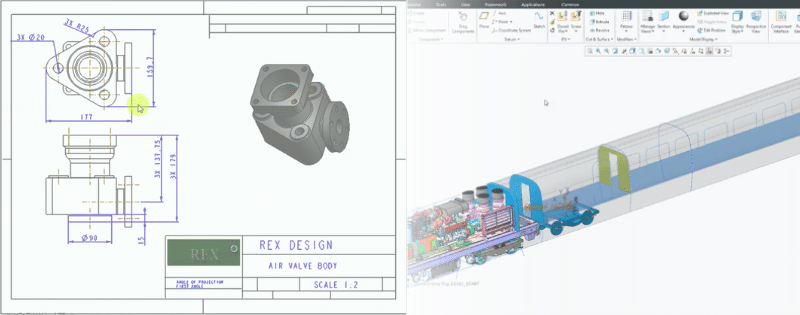

To create these powerful machines, Fantom needed a 3D CAD solution with both precision and flexibility. Their previous software, SolidWorks, didn’t provide the high-level functionality their designs required. SolidWorks’ inflexible structure complicated their need to focus squarely on one area of design without losing sight of the overall design itself. The software’s large assembly issues and lengthy design time were also stress factors on Fantom’s ability to create their vacuums efficiently.

PTC Creo: To the Rescue

Adding PTC Creo opened up new design possibilities for Fantom engineers. Now, they can load and display complicated models without overtaxing their systems. They can easily access the entire model without compromising functionality. And by limiting the level of details in inactive areas within the design, they can hone in on specific features while still viewing how everything fits together.

PTC Creo allows multiple engineers to work on different areas of the same model at the same time. Without competing versions floating around, the team can ensure complete synchronicity.

The Creo Edge

Fantom’s CEO, Adnan Tangün, says the only way to remain competitive in a global market is through continued investment in R&D and production technologies.

By adding PTC Creo, Fantom cut their product introduction time and product failures by 30 percent, increasing both the efficiency and the quality of their design process. With PTC Creo, they’ve found a solution that keeps them on the cutting edge of vacuum design.