Thomas Built Buses, a subsidiary of Daimier Truck North America, has engineers that design all types of vehicles: school buses, blood mobiles, and even correctional transport are all part of their product lines. Their company website says it best: “We’re committed to building buses that give you peace of mind day after day, mile after mile.”

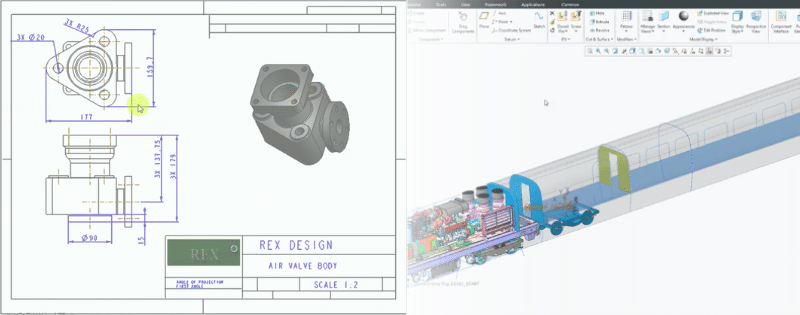

Each customer’s bus is custom-made by Thomas Built, which means that the company relies on standardization to avoid sloppy mistakes. That’s where the PTC Creo Piping and Cabling Extension (PCX) comes into play.

PTC Creo PCX is an invaluable tool for designers who have to work with wires, pipe, flexible hose or harnesses. Its routed systems design capabilities allow you to input piping parameters into the design, like minimum and maximum allowable bend radii. The system then verifies adherence to the standards set in place while piping and cabling are routed.

Using Creo PCX, engineers are able to use virtual prototypes to test multiple iterations of piping routes in the same design before moving into the production phase. This helps void the costly side effects of labor and scrap that go into physical prototyping.

Most importantly, the engineering team can trust that the final design is accurate and error-proof when it moves into production.

By deploying Creo and Creo PCX, Thomas Built has been able to increase their productivity by 200%.

Questions? Give Us a Call

Let us know if you’d like to discuss whether Creo Piping and Cabling Extension might be a game changer for your company. 3 HTi does extensive consulting and process assessments on design and manufacturing processes. Creo isn’t for every organization, but it can be revolutionary for many. Let’s talk and see what your company might be able to do to increase efficiencies.

We’re available at (866) 624-3HTi, and we’ll be happy to answer your questions.