The Part Management Challenge with PLM

3 HTi have been experts in the PLM industry for over 20 years. We have seen PLM systems play a tremendous role in improving part management and security, but the significant limitation of PLM is data access. Assigning attributes to make files accessible requires human effort, but this can be a little unreliable. Synonyms, errors, and global language all conspire to make designs invisible to attribute-based search.

The Part Management Challenge with PLM

Because of these challenges and reliance on human effort, PLM search is complex. Most searches rely on the user knowing the filename or part number of the item they are looking for, which is not practical.

“What we realized is that we couldn’t reuse what we couldn’t find. We don’t need the ability to search for something. We need the ability to find something.”

Dana Nickerson, Whirlpool Corporation

Two Bad Outcomes

Search frustration quickly leads to abandoned searches, causing new parts being designed or sourced from scratch. The result is a growing rate of duplication that affects your bottom line for years to come. One study showed a cumulative cost of developing a new part exceeding $20,000, not including tooling or fixtures.

Another bad outcome is lost access to meaningful information for new part development. If an engineer or purchasing agent can efficiently find existing similar designs, they can create fast and accurate cost estimations; a short-list of potential supplier which are already making similar items; useful insights into warranty cost; access to manufacturing plans and tool path programming; and so much more.

Shape is the Solution

All parts have shape. The challenge is capturing the shape of complex parts and assemblies in a manner that is comprehensive, concise, and comparable. Many attempts have tried to use parameters such as surface area or volume as the basis for part search but haven’t been able to provide the needed accuracy.

“Yet most engineering departments [that have tried to move beyond attribute search] are still limited to out-of-date parametric search tools that produce either thousands of hits or no hits at all, forcing frustrated engineers to simplify design new parts from scratch.”

Accelerating Innovation with New Data Strategies; tdwi.org

A New Approach

3 HTi partnered with iSeek to help our clients solve these issues. The founders of iSEEK Corporation, Drs. Abir Qamhiyah and Don Flugrad, set out to solve the problem of inadequate part search using an approach based in large part on techniques of pattern recognition. The result is CADseek, a patented technology that mathematically transforms shape into a numerical signature (a geometric fingerprint for each CAD design), and which meets the requirement of being comprehensive, concise, and comparable. Each CADseek search is not only comprehensive and clutter-free but includes reliable scoring of the degree of similarity between the search target and each match, encompassing all facets of shape.

Shape correlates with many part characteristics including function, cost, and performance, allowing the CADseek technology to be applied in two broad categories of use:

- Analytics: analyzing an existing CAD database(s) using the dimension the shape to find duplication, opportunities for standardization, and unwarranted variances in cost and performance;

- Search to find reuse opportunities, relevant information of similar tested designs, and to guard the PLM against attempts to submit new duplication.

Providing Tools Where They’re Needed

Eliminating and avoiding duplication, as well as tapping into the reservoir of knowledge contained in existing designs, helps companies achieve their business goals via three critical elements:

- First, designers and purchasers need search tools that are efficient and accurate to avoid abandoned searches and enable finding reusable parts.

- Second, those tools should be available within preferred workflows, including CAD and PLM applications.

- And third, positioning a watchdog at the PLM to alert employees and managers of missed reuse opportunities creates accountability for corporate efficiency goals.

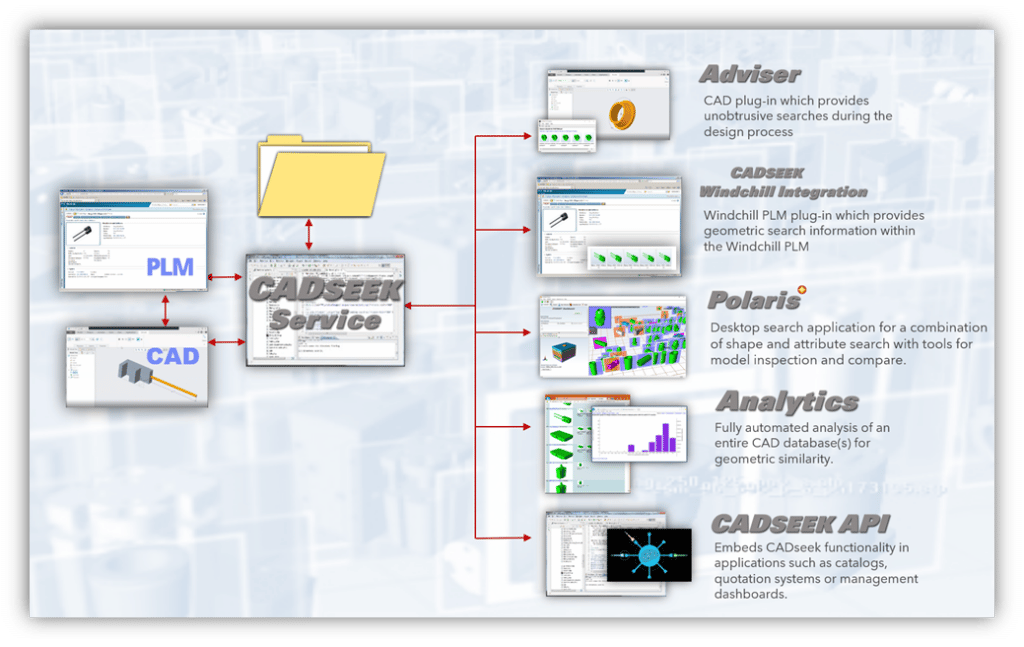

The CADseek technology is available as a suite of tools that all work from the same central infrastructure. Users search geometrically similar models in Creo with CADseek Adviser, in Windchill with the CADseek Windchill Integration, as a stand-alone search application with CADseek Polaris, and in dashboards, catalogs and other applications via the CADseek API.

If you would like to discuss more about reducing your costs and running more efficiently, contact us here