A common misconception of digital transformation for engineering is that technology will replace human workers. DX should empower and compliment human capital, not replace it. Look no further than the definition of Industry 5.0 — it is the relationship between man and machine and coined the term “cobots” — cooperation between humans and machines. In the post-COVID industrial landscape, companies are finding the human element harder to solve than the technologic.

The State of the US Manufacturing Workforce

The Association for Advancing Automation shows Q1 and Q2 as record quarters for investment in robotics. Fortune Business Insights predicts the global digital transformation market will reach a value of more than $3.5 billion by 2028 with a compound annual growth rate (CAGR) of 22.1 percent. Clearly, companies value investment in DX. The missing piece right now is human workers with the skill set to compliment this tech investment. Between the great resignation and an unemployment rate under 4%, manufacturers struggle to find and train enough workers to maximize their investments. Emphasis on reshoring only increases the pressure for US manufacturers to solve their worker crisis.

The American Society of Mechanical Engineers (ASME) recently completed a study examining the worker skills gap. They uncovered a problem so widespread that it could dampen the manufacturing industry for years to come. The ASME report focused on three common roles in manufacturing companies that will see the most notable changes in terms of how digital transformation will alter workflows and methodology. Those roles are Machinist, Mechanical Engineer and Manufacturing Engineer. First and foremost, academia needs to evolve and teach deeper Design for Manufacturing (DFM) knowledge. In practice, workers in all three of these roles will need to collaborate and learn more of each other’s jobs to improve productivity, efficiency and time-to-market. New titles, new definitions and different types of engineers are evolving from the use of technology. Educational curriculum should feature overlap and interdisciplinary work outside of a silo or a business unit. Creating well rounded, viable engineers that are able to better understand not only their specialty but how their specialty engages with other aspects of the engineering process can solve the challenge of a dwindling workforce.

Essential Changes to Three Roles in Industry 4.0

Mechanical Engineers

Mechanical engineers must continue to improve engineering designs while becoming more involved in manufacturing implementation and processing production data, improving designs for manufacturability. When surveyed, 60 percent of industry leaders believe interdisciplinary engineering knowledge will increase for mechanical engineers over the next five to 10 years. This was consistent across small, medium, and large manufacturers. Continued emphasis on “soft” skills like problem solving and communication skills to complement their focus on software tool functionality, data analytics, programming, and smart and sustainable design techniques.

Manufacturing Engineers

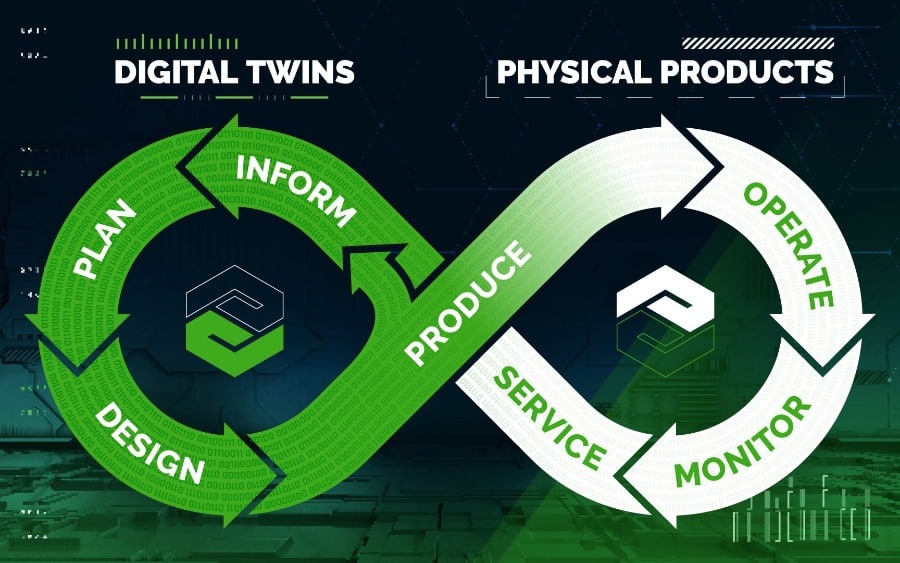

Manufacturing engineers will become even more interdisciplinary as this role blends skills with both mechanical engineers and CNC machinists. 72 percent of ASME’s survey respondents believe human-robotic interaction will increase and 74 percent believe automation will increase for this role. Like mechanical engineers, manufacturing engineers will need enhanced communication skills and will be expected to incorporate additive manufacturing and use artificial intelligence/machine learning (AI/ML), digital twins, and data analytics to improve throughput and efficiency.

CNC Machinists

CNC machinists’ roles will evolve dramatically, from a CNC operator to an engineering technician who programs CNC machines. Over time, CNC machinists should take on other manufacturing engineering functions. The factory environments in which future CNC machinists will work will become more complex, using cobots, 3D printers, AI/ML and multi-axis machines. They will need greater “mental dexterity” (such as programming) and productive collaboration with engineering teams. This role will require workers who are increasingly fluent in computer-aided design and manufacturing (CAD/CAM) software. Better programming skills will enable machinists to increase their use of technology such as five-axis machines (65 percent), additive/hybrid manufacturing (66 percent), and robots/cobots (65 percent).

But Wait, There’s More

The report also found trends that will span manufacturing regardless of role:

Communication is paramount: an increased focus on exchanging data between groups of people through cloud collaboration. Digital transformation of roles will shape communication as workflows change. Some 86 percent of respondents agreed that there is a need for a collaborative design process between all three disciplines.

Certifications show specialization: Academia will supplement degrees with certifications. Degrees will serve as the foundation, while certifications will showcase specialized skills—86 percent of academics embrace less reliance on degrees and welcome more specialized certifications developed in partnership with industry, while 84 percent of all survey respondents believe employers and academia should partner on new types of certification programs based on employer needs.

Academia embraces emerging technology: Technologies including generative design (GD), AI/ML, augmented reality/virtual reality (AR/VR) will be pervasive—80 percent of academics believe GD will be an important skillset and 67 percent believe AI or ML will be an important product design skill for mechanical engineers.

CNC machining is changing rapidly: 65 percent of industry believe use of robotics will increase and 62 percent believe use of programming skills to program smart products will increase.

No more “throwing it over the wall”: Mechanical engineers need to have applied knowledge throughout the manufacturing process, rather than designing a part and then leaving it to machinists to sort out the procedures required—79 percent of industry believe electrical and software engineering will increase while 77 percent believe system engineering skills will increase.

A Shorter-Term Solution

A major shift is required to solve these problems, starting in academia and how manufacturers train their engineers and machinists. In the near term, information capture and “doing more with less” can give forward-thinking manufacturers and edge while waiting for the wave of i5.0 workers to arrive. Smart investments in technology like augmented reality for digital work instructions empowers your team. Benefits of an AR strategy include:

- Optimization of critical workflows

- Streamline of knowledge transfer

- Easier compliance and traceability

- Reduced risk for frontline workers

- Ability to close the skills gap in your existing workforce

Schedule a conversation with one of 3 HTi’s digital transformation experts to learn more about our turnkey suites of AR solutions, including software and rugged wearables built for industrial workplaces.