Desktop Metal 3D Printers

Desktop Metal’s goal is to deliver on the vision of mass production 3D printing. Production 3D printing can produce more advanced parts and products that can truly change the world at high, meaningful volumes.

Desktop Metal’s goal is to deliver on the vision of mass production 3D printing. Production 3D printing can produce more advanced parts and products that can truly change the world at high, meaningful volumes.

In an effort to drive production 3D printing to the masses, Desktop Metal also offers qualified materials to ensure that users can 3D print with success and deliver the high-quality parts needed for end-use production

You won’t find a more flexible Additive Manufacturing solution for the long term. DM’s materials library spans virtually every category, from metals and polymers, to ceramics, composites, and even upcycled materials such as wood. In-house team of world-leading materials scientists and leading industry partners combined to develop the library of print materials.

Compare our solutions to find a printer and materials that fit your Additive Manufacturing needs.

Office-friendly production of metal prototypes and one-off parts. Just Print. And Sinter.

PRINTER TECHNOLOGY: Bound Metal Deposition (BMD).

MAX BUILD RATE: 300 x 200 x 200 mm

RESOLUTION: 0.40 mm nozzle diameter, standard resolution

LAYER THICKNESS: 50–150 μm in green state, high resolution printhead

Turnkey batch production of fully dense, customer-ready metal parts.

PRINTER TECHNOLOGY: Binder Jetting

MAX BUILD RATE: 16L — 350 x 220 x 200 mm

12L — 350 x 220 x 150 mm

8L — 350 x 220 x 100 mm

4L — 350 x 220 x 50 mm

RESOLUTION: 1600 dpi (1 PL native drop size)

LAYER THICKNESS: 50 μm – 100 μm

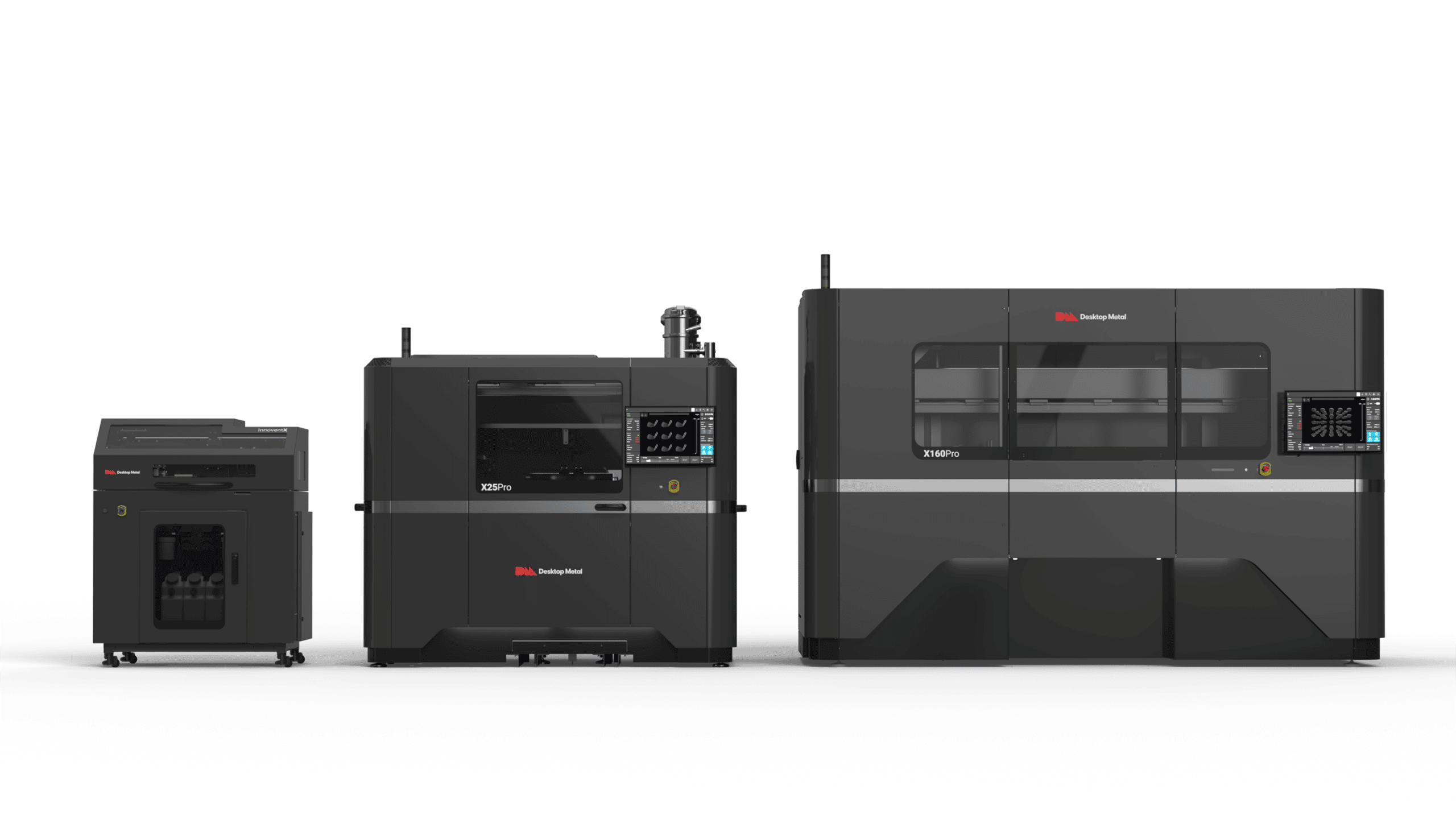

Binder jet 3D printing of metals or ceramics, featuring patented Triple ACT. Three models offered: the InnoventX, the X25Pro and the X160Pro.

PRINTER TECHNOLOGY: Binder Jetting, with Triple Advanced Compaction Technology

MAX BUILD RATE: 800 x 500 x 400 mm — X160Pro

400 x 250 x 250 mm — X25Pro

160 x 65 x 65 mm — InnoventX

RESOLUTION: > 30 µm voxels for all models, based on using a 10 picoliter printhead and 30 μm layer. Results may vary based on materials and other factors.

LAYER THICKNESS: 30 μm – 200 μm

From desktop production of small parts to 24/7, lights-out manufacturing to large, production-grade printers, ETEC solutions address a wide range of production scales across over 190 compatible materials.

PRINTER TECHNOLOGY: Digital Light Processing (DLP)

MAX BUILD RATE: 143 x 83 x 110 mm and up

RESOLUTION: 25 – 100 µm with patented pixel tuning

LAYER THICKNESS: 25 – 175 µm