One of the biggest challenges facing manufacturing companies today is managing changes and updates at any time during the product development process. An inefficient or broken Change Management process will add major delays and is a common reason companies are missing deadlines or sacrifice product quality. Ask yourself these questions…. When a change is made, how successful is your process to update everyone in the enterprise that needs to be aware of these changes? How successful is your process in notifying outside vendors and suppliers? Your success is tied to the process you use. Ideally you would want a notification to go to the correct people (inside and outside the enterprise) automatically, giving them insight about who made the change, the reason for the change, etc.

A concept that helps greatly is the concept of “associativity”. This means that a change made anywhere is a change made everywhere. This means that changes are automatic, thus updating Bill of Materials, CAD drawings, Tool Path for manufacturing, Supplier Materials, etc. The idea is to avoid mistakes up-front and communicate changes and updates early. ERP systems cannot do this as they only update text files and not CAD or any graphics files.

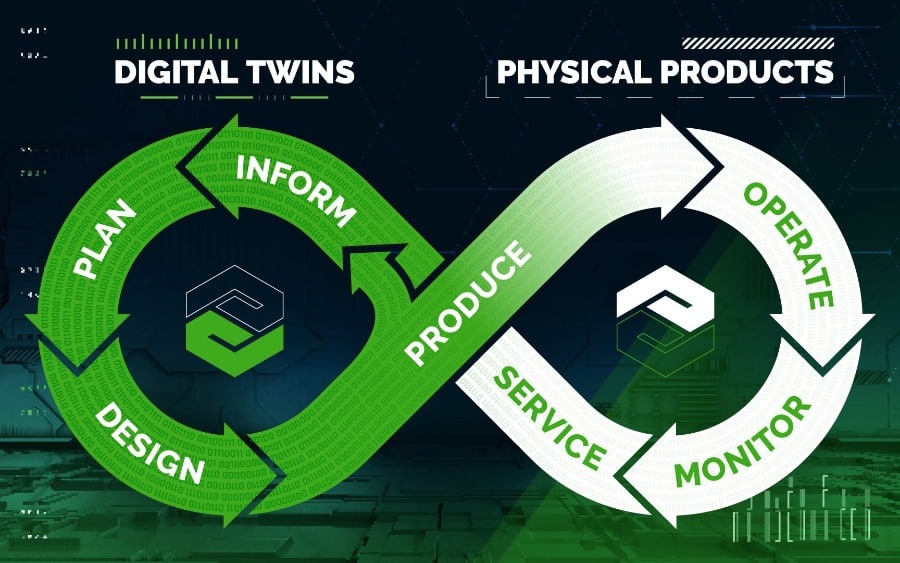

Windchill PLM (Product Lifecycle Management) provides powerful tools to manage all data (including CAD and other graphics files) and all processes of your product development/new product introduction processes. Windchill will manage all changes throughout your processes. Here are a few ways in which Windchill improves the efficiency of change management:

- Centralized Change Management: Windchill provides a centralized repository for all product-related data, including design files, bills of materials, and change orders. This allows teams to track changes in real-time and ensures that all team members are working with the latest product data.

- Automated Workflows: Ensuring that change requests are properly evaluated, approved, and implemented. This reduces the risk of errors or delays in the change management process.

- Traceability: Full traceability of changes throughout the product development process. This allows teams to track changes from their initial request to final implementation and ensures that any issues or errors can be easily identified and resolved.

- Collaboration: Powerful collaboration tools that enable team members to work together on change requests. This ensures that all team members are kept informed and able to provide input throughout the change management process.

- Analytics: PLM systems can provide advanced analytics and reporting capabilities to help teams track key metrics related to change management, such as the time to implement changes, the number of change requests, and the impact of changes on product quality.

- Associativity: As mentioned earlier, a change made anywhere is a change made everywhere. Changes are automatic, thus updating Bill of Materials, CAD drawings, Tool Path for manufacturing, Supplier Materials, etc.

By using Windchill PLM, organizations greatly reduce the risk of errors or delays in the change management process, improve collaboration and communication among team members, and ensure that changes are properly evaluated and implemented to support the successful development of high-quality products. We at 3 HTi have seen our clients gain an approximate 5x to 12x the return on investment during the first year. By increasing their communication speed this helps them bring products to market faster and measurably increases profit.