Back in May when I was at PTC LiveWorx in Boston, PTC ran a video during the first general session regarding the success of Cummins’ Sustainability Initiatives in utilizing PTC solutions. When the video started I wasn’t sure what “sustainability” meant for manufacturers, but I was very impressed by the video. David Genter, Director of Design Engineering at Cummins was interviewed and his testimony was easy to understand, to the point and overall impressive. To me, this was the most sincere and direct customer success story video I have seen from PTC.

When you hear the term “Sustainability” in regards to Manufacturing, what does that mean to you? Many small to mid-sized manufacturers may think this is an initiative for large manufacturing companies and that a sustainability initiative needs to involve complex processes. Or, that the products they make do not fit the profile for sustainability. Therefore, you may believe that a sustainability initiative is too costly and does not apply to your business. But what really is sustainability and what can it mean to you and your business?

Sustainability initiatives in manufacturing are undertaken to:

- Minimize their environmental impact

- Conserve resources – reducing materials use and scrap

- Promote social responsibility throughout their production processes.

- Compliance with regulations

- Improving brand reputation

- Create a more resilient and responsible manufacturing sector

These initiatives aim to create more sustainable and environmentally friendly manufacturing practices while still meeting production goals and maintaining economic viability. While the message and focus of a sustainability initiative is to benefit the environment there is a by-product of benefits that manufacturers and their customers can reap. These include:

- Faster design cycles

- Faster speed to market for new products (finding optimal designs quickly)

- Reducing or eliminating scrap and re-work

- Using less materials

- Cost savings

- Empowering the Design and Engineering teams

- Improved product quality

- A culture that creates more meaning into all employees

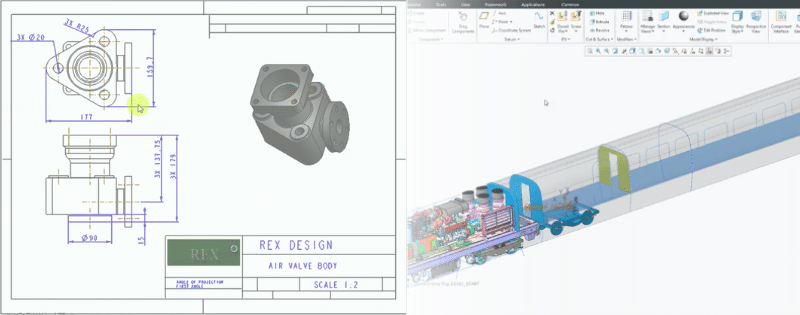

About 2 hours after watching the Cummins’ sustainability video, I got the opportunity to meet and talk with David Genter and learned that his passion for sustainability started back in his early days as at Cummins. One of the tools that was helping them meet their initiatives was Creo’s Generative Design extension. Using the power of AI, Generative Design in Creo autonomously creates optimal CAD model designs from a set of requirements which you specify. This delivers high-quality, lower-cost, ready-to-manufacture products, all within the Creo design environment. You can modify the results or use them as a final design. Normally critical design decisions are based on experience, assumptions and historical data. Without using an analysis tool to validate, this can lead to engineers overdesigning to compensate and that can create a lot of problems downstream. Verification and validation for the Generative Design extension include Von Mises Stress, Displacement and you have the ability to interrogate the results.

The Generative Design extension also helps explore constraints. You can set up a design for 3D printing, then run another design for 3-axis milling. Since you can generate multiple concepts quickly, using Generative Design is the fastest way to find the most optimal design in the shortest timeframe. David’s comment to me was that in over 30 years of Design and Engineering experience Generative Design gave him designs that he would never have thought possible.

The “Compounding” ROI of using Generative Design for a Sustainability Initiative

Adding profit to the bottom line is not the main focus of sustainability, but seeing a profitable return on an investment is always a major benefit. Here is how cost savings compound into a favorable ROI:

Material Cost Savings:

- Total Material cost savings for all parts

- Multiplied by the Number of products made using those parts

- Equals the Material Cost Savings Total

New Product Introduction Savings:

- Current hours spent developing new products – Man Hours across the enterprise

- Reduction of hours spent developing new products using Generative Design

- Amount and Value of Hours reduced using Generative Design – Man Hours across the enterprise

Increased Product Sales ROI:

- Increase in product sales due to:

- Increased sales revenues by introducing new products to market faster

- Reduced costs from improved product quality

- Public perception of increase in product quality reputation from:

- Increased reliability

- User cost savings from products working more efficiently (less fuel needed, maintenance, etc.)

Is it possible for you to reap financial benefits from sustainability while implementing a more environmentally friendly process? Ask yourself these questions: How can my company have a more environmentally friendly process or product? Does sustainability make sense for me? If you would like to talk with one of our experts, contact us at info@3hti.com. We can help you determine if sustainability makes sense or not for you. You can also contact us to learn more about Creo’s Generative Design capabilities.

Thanks for reading!

- Rob Romanoski, Director of Sales Operations, 3 HTi.