Product Lifecycle Management (PLM) is a strategic approach that integrates people, processes, business systems, and information to manage a product’s lifecycle from concept to disposal. This article explores the evolution, current trends, challenges, and future advancements of PLM in the manufacturing sector, highlighting how 3HTI’s expertise and solutions can help manufacturers stay ahead of the curve.

Key Takeaways

- Understanding PLM: Product Lifecycle Management (PLM) is essential for integrating people, processes, business systems, and information throughout a product’s lifecycle, enhancing efficiency and innovation.

- Historical Evolution: PLM has evolved from basic document management systems to sophisticated integrated solutions that streamline product development across various industries, including aerospace, automotive, and electronics.

- Current Challenges: Implementing PLM comes with challenges such as complexity and integration issues, data management and security, and user adoption. These challenges can be mitigated with advanced integration tools, robust security measures, and effective training programs.

- Future Trends: The future of PLM includes advancements in digital twins, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and cloud-based solutions. These technologies will further enhance product quality, predictability, and collaboration.

- Hypothetical Case Studies:

- Aerospace Industry: PLM solutions can streamline supply chain processes and ensure regulatory compliance, resulting in reduced time-to-market and improved product quality.

- Automotive Industry: PLM helps manage extensive design data and maintain consistency across global teams, leading to reduced design errors and increased efficiency.

- Medical Devices Industry: PLM ensures compliance with regulatory standards and traceability, leading to faster regulatory approvals and reduced product recalls.

- 3HTI’s Expertise: 3HTI offers comprehensive PLM solutions tailored to various industries, leveraging their expertise in sectors like medical devices, aerospace, and automotive. Their commitment to innovation ensures businesses can stay competitive and future-proof their operations.

- Call to Action: Manufacturers should explore advanced PLM solutions to stay ahead in the evolving market. 3HTI provides the expertise and technology needed to implement effective PLM systems, ensuring long-term success and adaptability.

Importance of PLM in Manufacturing

PLM plays a crucial role in streamlining manufacturing processes, enhancing product quality, reducing time-to-market, and ensuring regulatory compliance. By providing a single source of truth, PLM systems enable seamless collaboration across various departments, facilitating better decision-making and innovation.

I. Historical Background of PLM

Early Development of PLM

The concept of PLM originated from the need to manage product data and lifecycle processes efficiently. Initially, PLM solutions were basic document management systems focused on controlling product-related documents. Over time, these systems evolved into sophisticated solutions that integrate various aspects of product development, including design, engineering, manufacturing, and service.

Growth and Adoption in the Manufacturing Industry

The adoption of PLM gained momentum in the 1990s, driven by the need for improved collaboration and efficiency in product development. Early adopters, particularly in the aerospace, automotive, and electronics industries, leveraged PLM to streamline their operations, reduce costs, and enhance product quality. These industries set the benchmark for PLM adoption, demonstrating significant benefits such as reduced time-to-market and enhanced compliance with industry regulations.

II. Current Challenges and Solutions in PLM

Complexity and Integration Issues

One of the primary challenges in implementing PLM is the complexity involved in integrating it with existing enterprise systems such as ERP, MES, and CRM. These integrations are crucial for ensuring data consistency and enabling seamless workflows. Solutions to these challenges include the use of advanced integration tools and middleware that facilitate smooth data exchange between different systems.

Data Management and Security

Managing and securing vast amounts of product data is another significant challenge. As the volume of data grows, ensuring its integrity, confidentiality, and availability becomes critical. Advanced data encryption, access controls, and compliance with industry standards like ISO 27001 and GDPR are essential solutions to these challenges.

Adoption and User Training

The successful adoption of PLM systems often hinges on user acceptance and adequate training. Resistance to change and a lack of understanding of PLM’s benefits can impede successful implementation. Effective training programs and change management initiatives are crucial to overcoming these barriers and ensuring that users are comfortable and proficient with the new system.

III. Future Trends and Technological Advancements in PLM

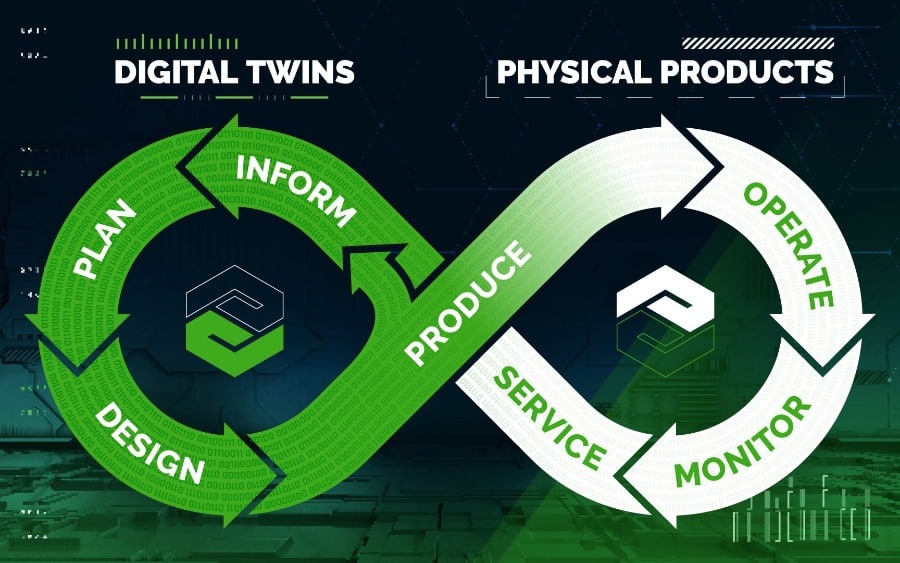

Digital Twins and Simulation

Digital twins are virtual replicas of physical products that enable real-time monitoring and simulation. By creating digital twins, manufacturers can predict and optimize product performance, identify potential issues before they occur, and enhance overall product quality. The integration of digital twins with PLM systems provides a comprehensive view of product data and lifecycle, facilitating better decision-making.

Artificial Intelligence and Machine Learning

The application of AI and ML in PLM is revolutionizing predictive maintenance, quality control, and process optimization. AI-driven analytics can provide insights into product performance, identify patterns, and predict failures, enabling proactive maintenance and reducing downtime. ML algorithms can optimize design and manufacturing processes, improving efficiency and reducing costs.

IoT and Connected Devices

The Internet of Things (IoT) connects physical devices to the digital world, providing real-time data that enhances PLM capabilities. IoT-enabled PLM systems can monitor product performance, track usage patterns, and provide valuable insights for continuous improvement. This connectivity ensures that manufacturers can respond quickly to changes and make data-driven decisions.

Cloud-based PLM Solutions

The shift towards cloud-based PLM solutions offers scalability, accessibility, and cost-efficiency. Cloud-based systems allow manufacturers to access PLM data from anywhere, facilitating remote collaboration and reducing the need for on-premises infrastructure. These solutions also offer flexible pricing models, making PLM accessible to small and medium-sized enterprises.

IV. Hypothetical Case Studies of Successful PLM Implementations

Hypothetical Case Study 1: Aerospace Industry

Overview: An aerospace company implements PLM to manage complex supply chains and ensure regulatory compliance.

Challenges: The company faced challenges in managing a complex network of suppliers and ensuring compliance with stringent aerospace regulations.

Solutions: By integrating Windchill for real-time collaboration and using ThingWorx for IoT-enabled monitoring, the company was able to streamline its supply chain processes and enhance compliance management.

Results: The implementation resulted in a 20% reduction in time-to-market, improved regulatory compliance, and enhanced product quality.

Hypothetical Case Study 2: Automotive Industry

Overview: An automotive manufacturer leverages PLM to handle large volumes of design data and ensure consistency across global teams.

Challenges: The manufacturer struggled with managing extensive design data and maintaining consistency in design processes across geographically dispersed teams.

Solutions: The implementation of Creo for advanced CAD capabilities and Windchill for centralized data management enabled better collaboration and design consistency.

Results: The manufacturer achieved a 30% reduction in design errors, a 15% increase in design efficiency, and streamlined collaboration across global teams.

Hypothetical Case Study 3: Medical Devices Industry

Overview: A medical device company adopts PLM to meet stringent regulatory requirements and ensure precise traceability.

Challenges: The company needed to comply with strict regulatory standards and ensure traceability throughout the product lifecycle.

Solutions: Windchill was used for comprehensive documentation and compliance management, while ThingWorx provided connected device monitoring.

Results: The company experienced faster regulatory approval, enhanced traceability, and reduced product recalls.

V. How 3HTI’s PLM Services Can Future-proof Your Business

Comprehensive PLM Solutions

3HTI offers a wide range of PLM solutions, including Windchill, ThingWorx, and Creo. These solutions are designed to address the unique challenges of different industries, providing customized and integrated PLM systems that enhance efficiency and productivity.

Expertise Across Multiple Manufacturing Sectors

With extensive experience in sectors such as medical devices, aerospace, and automotive, 3HTI has a proven track record of successful PLM implementations. Their industry-specific knowledge ensures that clients receive tailored solutions that meet their specific needs.

Future-proofing Through Innovation

3HTI’s commitment to innovation ensures that their PLM solutions incorporate the latest technological advancements. By staying at the forefront of PLM technology, 3HTI helps manufacturers future-proof their businesses, ensuring long-term success and adaptability.

VI. Conclusion

Recap of Key Points

This article has explored the historical background, current challenges, future trends, and hypothetical case studies of PLM in manufacturing. PLM plays a critical role in enhancing product development, ensuring compliance, and improving overall efficiency.

Call to Action

Manufacturers are encouraged to explore and adopt advanced PLM solutions to stay competitive in the evolving market. Contact 3HTI for a consultation and learn how their PLM services can benefit your business.

By providing a comprehensive exploration of PLM’s past, present, and future, this article showcases 3HTI’s expertise and offerings, demonstrating their ability to help manufacturers achieve their goals through advanced PLM solutions.

Frequently Asked Questions (FAQs)

1. What is Product Lifecycle Management (PLM)?

Answer: Product Lifecycle Management (PLM) is a strategic approach that integrates people, processes, business systems, and information to manage a product’s lifecycle from concept to disposal. It enhances product quality, reduces time-to-market, and ensures regulatory compliance by providing a single source of truth for all product-related data.

2. How has PLM evolved over time?

Answer: PLM has evolved from basic document management systems focused on controlling product-related documents to sophisticated integrated solutions. These advanced systems now manage various aspects of product development, including design, engineering, manufacturing, and service, providing comprehensive support throughout the product lifecycle.

3. What are the current challenges in implementing PLM?

Answer: The current challenges in implementing PLM include:

- Complexity and Integration Issues: Integrating PLM with existing enterprise systems like ERP, MES, and CRM.

- Data Management and Security: Managing and securing vast amounts of product data.

- Adoption and User Training: Ensuring user acceptance and adequate training to overcome resistance to change and lack of understanding of PLM benefits.

4. What are some solutions to these PLM challenges?

Answer: Solutions to PLM challenges include:

- Using advanced integration tools and middleware for smooth data exchange.

- Implementing robust data encryption, access controls, and compliance with industry standards like ISO 27001 and GDPR.

- Providing effective training programs and change management initiatives to ensure user proficiency and acceptance.

5. What future trends and technological advancements are shaping PLM?

Answer: Future trends and technological advancements in PLM include:

- Digital Twins and Simulation: Creating virtual replicas of physical products for real-time monitoring and optimization.

- Artificial Intelligence and Machine Learning: Using AI-driven analytics and ML algorithms for predictive maintenance, quality control, and process optimization.

- IoT and Connected Devices: Enhancing PLM capabilities through real-time data from connected devices.

- Cloud-based PLM Solutions: Offering scalability, accessibility, and cost-efficiency by allowing remote access to PLM data.

6. Can you provide examples of successful PLM implementations?

Answer: Yes, here are hypothetical case studies:

- Aerospace Industry: Implementing PLM to manage complex supply chains and ensure regulatory compliance, resulting in reduced time-to-market and improved product quality.

- Automotive Industry: Leveraging PLM to handle large volumes of design data and ensure consistency across global teams, leading to reduced design errors and increased efficiency.

- Medical Devices Industry: Adopting PLM to meet stringent regulatory requirements and ensure traceability, resulting in faster regulatory approvals and reduced product recalls.

7. How can 3HTI’s PLM services benefit my business?

Answer: 3HTI offers comprehensive PLM solutions, including Windchill, ThingWorx, and Creo, tailored to address the unique challenges of different industries. With extensive experience in sectors like medical devices, aerospace, and automotive, 3HTI provides customized and integrated PLM systems that enhance efficiency and productivity. Their commitment to innovation ensures that businesses stay competitive and future-proof their operations.

8. Why should manufacturers consider adopting advanced PLM solutions?

Answer: Manufacturers should consider adopting advanced PLM solutions to streamline their operations, enhance product quality, reduce time-to-market, and ensure regulatory compliance. Advanced PLM solutions incorporate the latest technological advancements, enabling manufacturers to stay competitive in the evolving market. Contacting 3HTI for a consultation can help businesses implement effective PLM systems and achieve long-term success and adaptability.

This article is a collaboration between 3HTI and OpenAI’s ChatGPT. Created on May 31, 2024, it combines AI-generated draft material with 3HTI’s expert revision and oversight, ensuring accuracy and relevance while addressing any AI limitations.

External Resources:

Here are four external articles that would be helpful to readers interested in learning more about the future of Product Lifecycle Management (PLM) in manufacturing:

1. PLM Trends 2024 | Future Of Product Lifecycle Management by SelectHub

- This article discusses key trends in PLM, including the integration of digital twins and digital threads, the use of augmented and virtual reality (AR and VR), and the shift towards cloud deployment. It provides insights into how these technologies are shaping the future of PLM and enhancing manufacturing processes.

- URL: https://www.selecthub.com/plm-trends-2024/

2. Digital Product Lifecycle Management in Consumer Goods by Deloitte

- Deloitte’s article explores the rapid technological advancements in the consumer goods industry and how digital PLM is adapting to these changes. It highlights the importance of digital transformation in product development and lifecycle management.

- URL: https://www2.deloitte.com/us/en/insights/focus/industry-4-0/digital-product-lifecycle-management.html

3. PLM Tech Trends and Challenges 2023 – Beyond Buzzwords by Beyond PLM

- This blog post provides an in-depth analysis of the current trends and challenges in PLM technology. It covers topics such as the evolution of digital threads, AI integration, and the increasing importance of cloud-based PLM solutions.

- URL: https://beyondplm.com/2023/09/03/plm-tech-trends-and-challenges-2023-beyond-buzzwords/

4. Future Trends Archives by Beyond PLM

- This archive contains a collection of articles focused on the future trends in PLM. It includes discussions on the digital transformation of PLM systems, the impact of AI and machine learning, and the integration of new technologies in manufacturing processes.

- URL: https://beyondplm.com/category/future-trends/

These resources will provide additional insights and perspectives on the evolving landscape of PLM in manufacturing.