Product design and simulation are handled by different software products, so in most companies, they are handled as separate processes. In some cases, they may even be handled by different teams within a single organization. In either case, separating the CAD design process and the product simulation process slows down everything. A slower process costs more, and adversely affects time to market, which can reduce lifetime product revenue.

Many organizations handle CAD design and product simulation as two complete separate entities.

Until now, there was no single product that could handle CAD design and product simulations, so companies were left to make the best of the disparate solutions available. PTC, the leader in 3D design and CAD, recognized this as an issue. They formed a partnership with simulation company Ansys, a ground-breaking company known for its simulation technology that helps companies turn their ideas into successful, innovative products faster and at lower cost than with other methods.

Until now, there was no single product that could handle CAD design and product simulations, so companies were left to make the best of the disparate solutions available. PTC, the leader in 3D design and CAD, recognized this as an issue. They formed a partnership with simulation company Ansys, a ground-breaking company known for its simulation technology that helps companies turn their ideas into successful, innovative products faster and at lower cost than with other methods.

Engineers Can Create Digital Twins Using PTC and Ansys

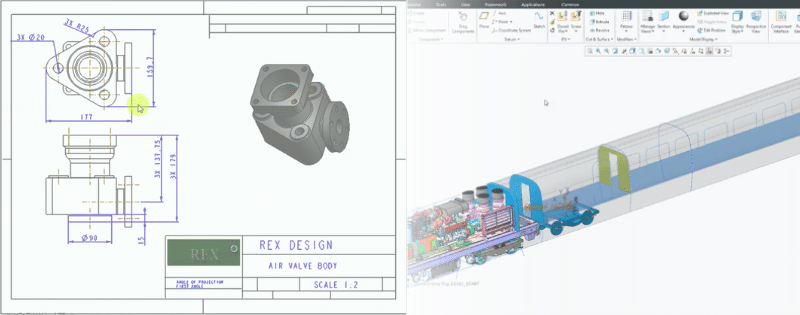

PTC will embed Ansys Discovery Live into its Creo 3D CAD solution to help engineers create better products faster and at a lower cost than before. The combination of Creo and Ansys allows engineers to make changes and immediately see the results of the changes in simulation, potentially cutting days or weeks from the design process.

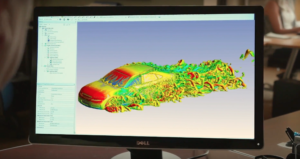

The digital twin created by Creo and Ansys provides a complete 3D visualization of the product as it experiences the stresses it would face when used in the real world. Engineers and designers can immediately pinpoint product weaknesses or potential failure points to make design changes without having to undergo the expensive and time-consuming prototyping or field testing processes. Using a digital twin allows companies to gain early insight into a product’s performance.

Digital twins help engineers understand how products and parts will perform in the real world, allowing them to address issues earlier in the design process.

Digital twin technology can also be used in conjunction with IoT to design operational processes, quickly diagnose performance issues, and eliminate bottlenecks or non-value-added steps that can delay delivery and increase costs.

The combination of Creo and Ansys Discovery Live will improve time to market, reduce costs and improve the quality of new and existing products by eliminating potential problems and increasing the product’s mean time between failure without adding unnecessary costs.

Creo and Ansys Availability for Digital Twin Processes

PTC announced the new partnership in late June at its LiveWorx 18 user conference in Boston. PTC CEO Jim Heppelman demonstrated using a prototype of the embedded Ansys solution from the mainstage. PTC’s announced intention is to continue adding more Ansys Discovery Live capability with each new release of Creo. This is the same highly successful approach it took in 2017 when PTC embedded Ansys Twin Builder into PTC ThingWorx Industrial Innovation Platform.

Benefits of Creating a Digital Twin with Ansys and PTC Creo

The Ansys/Creo combined solution provides customers with a unified modeling and simulation environment. This integrated capability removes the current disconnect between CAD and simulation, helping improve the productivity of design engineers by quickly providing insight into the ramifications of the many design decisions they make at every stage of the development process. The result will be higher quality products, lower costs, and faster time to market.

By creating a combined design-simulation solution, organizations can create higher quality products, and lower costs, with a faster time-to-market.

We’re one of the largest PTC distributors in the country, and we already think highly of PTC products, including Creo and ThingWorx. But in our opinion, the addition of Ansys Discovery Live is a game-changer that catapults PTC lightyears ahead of any other 3D CAD solution available. To learn more about Creo and the Ansys integration, contact us today.