It’s early days, but 2023 is shaping up to be the year of ChatGPT. The artificial intelligence (AI) tool from developer OpenAI dominates headlines in pop culture, tech, and business. A number of industries perceive it as a potential tool, or threat — it depends who you ask! Lawyers, doctors, teachers, marketers, software developers, authors, students, and more continue to debate the pros and cons of the tool and its expected competitors. What’s the impact of AI for engineers? Are tools like ChatGPT coming for the mechanical engineering profession?

What is ChatGPT?

In short, ChatGPT is an AI tool that delivers data and interacts with users in a conversational fashion. Unlike search engines, ChatGPT answers follow up questions, challenges premises, rejects inappropriate requests, and even admits mistakes. Its conversational delivery makes responses more digestible and interactive for its human counterparts, and also deliver greater detail than a typical search engine query that aggregates results from across the internet.

There are limitations to the tool. ChatGPT occasionally delivers wrong or inappropriate responses. The tool can be overly verbose. Also, the source database is not real-time, so requests for hyper-current information are inaccurate or incomplete.

Who is using it today?

Although ChatGPT seems like a novelty, forward-thinking professionals are exploring use cases for the technology. Some educators spoke out in support of the tool as an educational resource for students and teachers alike, while others such as New York City public schools banned it from use. State bars threatened an attorney who planned to use the tech to argue speeding tickets in court. Marketers and content creators are exploring potential uses for the tool, from chatbots and social media posts to blog writing (this one was 100% human-authored, we promise!) So, what AI tools are designers and engineers using? Is ChatGPT capable of disrupting product design?

ChatGPT and Mechanical Engineering

Roopinder Tara, a mechanical engineer, experimented with ChatGPT and published his results in an engineering.com blog several weeks ago. His results were mixed. It’s clear that ChatGPT capably responds to certain analysis requests. Mr Tara’s wife owns a masters of literature and gave a nod of approval to the bot’s evaluation of symbolism in The Scarlet Letter. However, technical calculations can give the bot trouble. It incorrectly evaluated a request to find the monthly payment for a 10 year, $100,000 loan at 5% interest. If ChatGPT can’t manage common financial calculations, what would it produce for advanced engineering calculations? Mr Tara inquired about the best failure theory for ductile materials. Here is Chat GPT’s response:

The most widely used failure theory for ductile materials is the von Mises yield criterion, also known as the maximum distortion energy criterion. This theory is based on the idea that failure occurs when the material reaches a state of maximum shear stress, or maximum distortion energy. This theory is applicable to ductile materials that undergo plastic deformation and is relatively simple to use in engineering calculations.

It states that failure will occur when the von Mises stress, which is the equivalent stress, reaches the material’s yield strength. The von Mises stress is calculated as the square root of the sum of the squares of the principal stresses, divided by the square root of two.

This theory is widely used for ductile materials because it gives a good representation of the behavior of the material under complex loading conditions, it’s easy to use and it’s relatively simple to implement into engineering calculations.

The author was impressed with the output, saying “it expounded on the results so eloquently that were I still teaching “Strength of Materials,” I would have given ChatGPT full points.” Not bad for a bot, but after more experimentation the ultimate conclusion raised a number of red flags. ChatGPT remains quite far away from displacing human engineers.

Any AI for Engineers that I can use today?

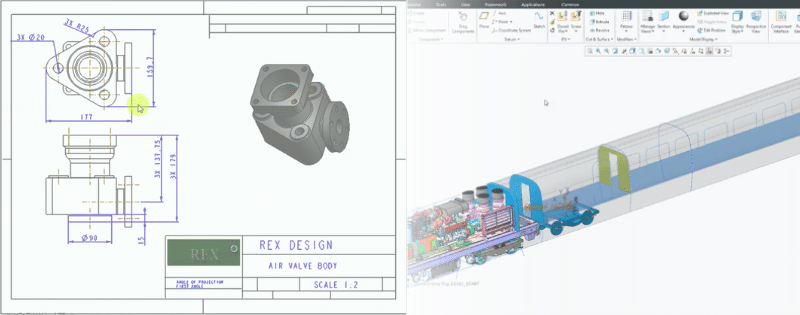

Fortunately there are AI tools that can help engineers design better products right now. You might even be using them already! One of the most powerful AI tools for mechanical engineers and product designers is generative design. Generative design asks product designers to construct a ‘study’ – that is, they define the problem they want to solve, using the language of design constraints, loads, materials, and manufacturing methods. The software then studies that problem, doing countless iterations, and returns an optimum set of solutions to the product designers, who then choose which ones they wish to refine. Remember, each of those solutions meets requirements, with countless iterations resulting in solutions the design team could not have devised in the time they had and might never have thought of.

PTC’s Creo software released generative design tools with Creo version 7.0.2. Creo’s generative design tool received plaudits from ABI Research as an industry-leading solution in 2022 and continues to set the standard. In addition to being easy for designers to use thanks to its integration into the familiar Creo UI, there are four reasons why generative design is more reliable and effective than traditional design workflows:

You’re building requirements into the design. All products start with requirements. These requirements could be driven by system engineering models tied into the product’s requirements and managed in PLM, as is possible in Creo. Or you can use requirements you’ve validated yourself in the course of earlier design work. The point is that with generative design, applying requirements to your model is part of setting up your study. Again, every solution that study returns will meet those requirements.

The manufacturing method informs the design. Typically, you’d design your part, validate it using simulation and analysis tools, do some more design work with the results, and then turn the part over to the process engineer for the first of several rounds of feedback before the design was finalized. With generative design, the manufacturing methodology is included in your requirements.

Using generative design saves time because you add manufacturing criteria to your study. This ensures you’ve gotten the design off to the best possible start before you call in your colleague’s valuable, specialized expertise.

These include:

- A build direction for parts that will be 3D printed.

- A parting line for parts that will be cast or molded.

- A linear extrude for parts that will be extruded or machined.

You generate multiple concepts quickly. Think back to how you approach an initial design phase. Maybe a handful of concepts? If you’re like most professionals, you’re also going to go back to what your hard-won experience shows you is likely to work. With generative design, the software iterates far faster than humans can – and without bias. Now your professional judgment goes in to setting up that well-conceived study.

You can modify the resulting model in the Creo design environment. The part model that generative design creates produces B-rep (boundary representation) geometry. Work on it in Creo just as you would any of your models.

3 HTi Resources for AI-Empowered Engineers

If you’d like more information on generative design capabilities in Creo, check out our YouTube page for a recorded overview and demo. For more detail, in-depth inquiries, or a custom demo, contact our experts here.