When they hear Creo, many people automatically think “Parametric,” since PTC’s groundbreaking parametric CAD/CAM solution is the genesis of Creo. But the name change is more than marketing hijinks—Creo Parametric offers capabilities far beyond just parametric modeling.

The latest version of Creo comes in five tiers, as explained here, but the tiers are more than just a change to the pricing. Each tier is thoughtfully designed to include advanced capabilities and package extensions that work together seamlessly to simplify the design process.

The new Creo packages include capabilities that work together to simplify the design process.

Essential Creo Parametric Capabilities

Parametric Modeling

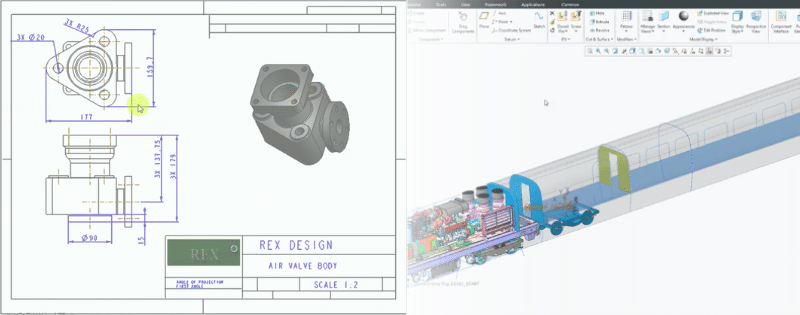

Creo provides the power and control of 3D parametric modeling in a flexible and easy-to-use way that rivals the simplicity of direct modeling. Designers can quickly and easily create free-form shapes and surfaces and run 2D and 3D simulations that recreate real-world operating conditions to help gauge performance and calculate MTBF (Mean Time Between Failures) and maintenance requirements. Creo includes online training and embedded tutorials that help get you up and running fast.

Creo provides the power and control of 3D parametric modeling in a flexible and easy-to-use way that rivals the simplicity of direct modeling. Designers can quickly and easily create free-form shapes and surfaces and run 2D and 3D simulations that recreate real-world operating conditions to help gauge performance and calculate MTBF (Mean Time Between Failures) and maintenance requirements. Creo includes online training and embedded tutorials that help get you up and running fast.

Creo provides the power of direct and parametric modeling within a single platform.

Collaboration

In today’s work environment where teams can be spread around the world and customers and suppliers are integral parts of design teams, sharing and collaboration are core requirements, and Creo easily shares data with other solutions and provides secure collaboration capabilities. It’s easy to work with data from other solutions, even competing CAD systems, without the need for cumbersome file conversions, still another way Creo supports collaboration.

In today’s work environment where teams can be spread around the world and customers and suppliers are integral parts of design teams, sharing and collaboration are core requirements, and Creo easily shares data with other solutions and provides secure collaboration capabilities. It’s easy to work with data from other solutions, even competing CAD systems, without the need for cumbersome file conversions, still another way Creo supports collaboration.

Creo helps streamline collaboration using Unite Technology.

Advanced Tools

Creo also enables quick design alternatives that allow engineers and stakeholders to evaluate performance characteristics as well as a product’s look as rendered by stunning 3D graphics. And as part of its digital twin and augmented reality capabilities, Creo includes human factor analysis that can help design efficient and safe production processes without having to set up physical prototype lines, saving both time and money while improving time to market.

Creo also enables quick design alternatives that allow engineers and stakeholders to evaluate performance characteristics as well as a product’s look as rendered by stunning 3D graphics. And as part of its digital twin and augmented reality capabilities, Creo includes human factor analysis that can help design efficient and safe production processes without having to set up physical prototype lines, saving both time and money while improving time to market.

Built-in support for IoT sensor-connected devices and equipment provides design and process feedback in real-time. Plus, the inclusion of Mathcad Express helps ensure that the right formulas are available for virtually any design, resulting in quick and accurate specifications.

Creo includes advanced features to support the latest technology, including IoT and AR.

Available Creo Parametric Extensions:

While these capabilities alone make Creo a standout in 3D design tools, the addition of various package extensions with each successive license tier puts Creo well ahead of any competitor.

- Piping and Cabling: Finding the best route for piping and cabling can be hit or miss, and even minor deviations can add to assembly costs, erode quality, and complicate maintenance. This Creo parametric extension captures all relevant information and design rules to arrive at the optimum layout quickly.

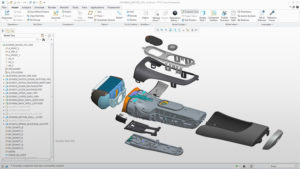

- Advanced Assembly: This extension simplifies the design of complex assemblies by enabling controlled collaboration through the use of configurations and skeleton models so that design work can be shared efficiently across extended teams without creating chaos.

- Prismatic and Multi-Surfaces Milling: This tool improves the design of tooling and factory equipment for NC milling and helps to increase milling machine productivity.

- Expert Moldbase: Designers can start in a 2D environment, and this extension automatically converts it to a 3D model. It includes a full line of standard parts and allows engineers to create custom additions to the library.

- Mold Machining: This extension enables a simplified design process for complicated one-off or low-volume production. Despite the ease of creation, the extension handles complex designs and automatically recalculates machining paths for design changes.

- Additive Manufacturing: Unlike many other CAD solutions where additive manufacturing is an afterthought, Creo Parametric’s additive manufacturing extension is an essential part of the toolset. It enables designers to create complex variable lattice structures and connects directly to printers to ensure accuracy. It helps designers build better products and ensures stakeholder buy-in through 3D augmented reality.

- Interactive Surface Design: This extension captures the outlines and curves of free-form product designs and converts them by manipulating tangency and curvature, so the original design concept is captured flawlessly in multiple planes. Engineers have complete control over how surfaces connect and help eliminate concerns about surface quality by using reflection points to pinpoint and eliminate flaws.

- Behavioral Modeling: This extension helps simplify and speed up the design process by streamlining the iterative process of balancing and optimizing requirements. In the event of conflicts, the systems help engineers make trade-offs that optimize the design for performance, cost, quality, or other priorities.

- Mechanism Dynamics: Your team needs to understand the dynamic forces your designs must withstand in the real world, but real-world tests are expensive and time-consuming. Mechanism Dynamics analyzes friction, gravity, and other static and dynamic forces to provide rapid insight into performance and reliability.

- Tolerance Analysis: This extension enables engineers to document geometric tolerances directly in the 3D CAD model to evaluate worst-case performance and statistical predictions of final assembly measurement distributions.

- GD&T Advisor: GD&T (geometric dimensioning and tolerance) advisor helps reduce the error between as-designed and as-produced products using a simple advisor-tree UI to show errors and warnings.

- Layout: Teams today use a variety of tools and formats. Creo parametric layout extension lets team members move easily between 2D and 3D design data to quickly produce 3D models and to control and manage updates and changes.

- Collaboration for CATIA and Siemens NX: Since not all stakeholders use the same tools, it’s important to ensure that changes made in third-party apps such as CATIA and Siemens NX are reflected accurately in Creo models. This extension does exactly that, quickly and easily promoting changes across models.

- Simulate: Using a comprehensive set of finite product elements, this extension analyzes and optimizes meshing, structural, and thermal characteristics.

- Fatigue Advisor: Improving reliability helps control costs and minimizes downtime and service costs. Fatigue Advisor simulates and improves the fatigue performance of designs using advanced techniques such as plastic strain interpolation.

- Flow Analysis: This calculates internal and external flows and creates animated flow results in real time. It analyzes flow, air, and turbulence to optimize molding performance.

- GD&T Advisor Plus: In addition to the capabilities in GD&T Advisor, the Plus extension allows the use of existing annotations created in Creo and provides the guidance necessary to ensure they are fixed to standards.

- Production Machining: This tool gives manufacturing engineers the ability to program NC machines directly when cutting and shaping product, whether on milling, turning, or wire EDM machines. Because this extension is integrated directly with Creo, design changes are automatically incorporated into the NC programming.

- NC Sheet Metal: This extension helps eliminate waste and reduce scrap, whether cutting, bending, or punching the design. It helps bring products to market faster while reducing costs and simplifying the manufacturing process.

- Mathcad: Mathcad includes all formulas and mathematical terms necessary for robust and accurate product design, in a format that is more intuitive and easier to use than spreadsheets.

- Advanced Simulation: This tool allows engineers to analyze the impact of non-linear stresses that extend beyond the elastic regions into plastic deformations.

- Complete Machining: This extension provides for prismatic milling and advanced NC-controlled capabilities to the analysis of models. It includes tools for simulating multi-axis machining, 2.5- to 5-axis mills, 2- to 4-axis lathes, 2- to 4-axis wire EDM, and multi-task machines. It comes complete with an extensive tool library and proven manufacturing templates.

- Options Modeler: This extension helps engineers quickly create customer-specific products derived from a modular product architecture. It enables the creation of product models and delineates how product modules interface or are assembled. It can shorten time to market and enable companies to meet complex customer requirements for unique or specific product functions.

- Topology Optimization: By analyzing stresses and strains, the Topology Optimizer helps create efficient designs by recommending the removal or reduction of unnecessary or redundant materials. It does not consider product aesthetics but does work within defined objectives and constraints to show which areas of a design are working efficiently.

- Additive Manufacturing Plus: This extension adds support for metal parts, allowing users to 3D print production parts directly from Creo without the multiple software parts most other printing solutions require. It also connects directly to the online Materialise library.

Need Some Creo Parametric Extensions?

Not every company will need all these extensions, so PTC has bundled them into the latest Creo offerings so that the most likely requirements for any company are available cost-effectively. More advanced extensions are available for companies with more complex needs.

To understand which Creo parametric extensions your company requires, talk to us at 3HTi to learn more.