When NASCAR announced a new body style for its 2013 season, it came years earlier than anyone expected. To make the cars resemble ones you’d see on the street, race car engineers had to scramble to redesign their vehicles based on manufacturer identity: make a Ford that looks like a Ford, or a Chevy that looks like a Chevy.

Source: pexels.com

Penske Racing, a company based in Mooresville, NC, had already begun working on a Dodge body when these new stipulations were handed down. They knew how to handle revisions like this, so they were prepared.

Turning on a Dime

Then, in a dramatic move, Penske’s management decided to switch from the Dodge body to a Ford body for the 2013 models. They’d have to scrap all of their work and start all over — streamlining a two years process into a process that would take less than 12 months. And, they had to do it all with the additional pressure of needing a model that could win.

It was clear that they needed a new engineering approach.

Creo to the Rescue

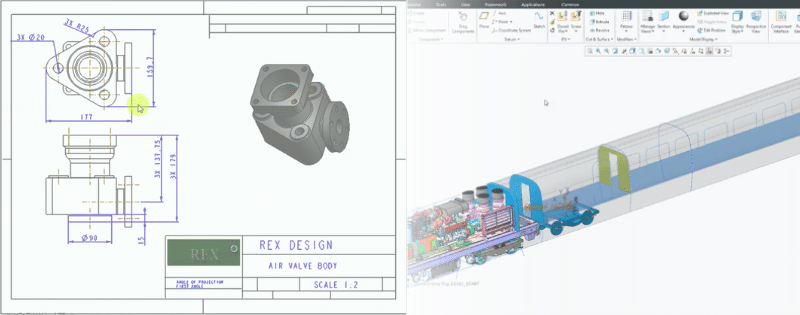

PTC Creo allowed Penske to try an engineering-driven approach to the Generation 6 car. Their engineers could now create and test components digitally first, and follow up with physical models that would be tested in wind tunnels and on the track.

Drew Kessler, the engineer responsible for the design group at Penske Racing, raves about the time this new process helped them save. The 80+ models they physically tested now came with useful information from digital tests that would help prepare them for what to expect in the real world. This ultimately increased the likelihood that the tests would be successful.

This also allowed Penske Racing to make decisions faster and achieve better performance for its development dollar.

The Creo Advanced Assembly Extension and PTC Windchill helped Penske’s engineering team collaborate smoothly; it was a perfect fit for working concurrently on automobiles, large-scale models that might overwhelm other 3D CAD software. Integrating parts from outside vendors, updating existing parts, creating new parts, and keeping track of new assemblies became a breeze.

The results speak for themselves. The Generation 6 team Penske Ford Fusion Sprint Cup cars made it from conceptualization to the race track in just 8 months — cutting design time by 66%. And, more importantly, the designs are winning races: five Sprint Cup competition races in 2014, three with Brad Keselowski’s #2 Ford Fusion, and two with Joey Logano’s #22 Ford Fusion. The team has also won three Nationwide Series races with Brad Keselowski in the #22 Ford Mustang.

“It all boils down to performance at the race track,” says Kessler. “We look at weight, safety, and a variety of other metrics. But in the end, what matters is providing the race teams with the tools they need to win. That’s how we know when we’ve done our job well.”

Kessler summed up the experience neatly: “We wouldn’t be able to do what we do without Creo.”

Interested in learning more about Creo and its 3D CAD capabilities? Read more about it here. Or why not contact us?