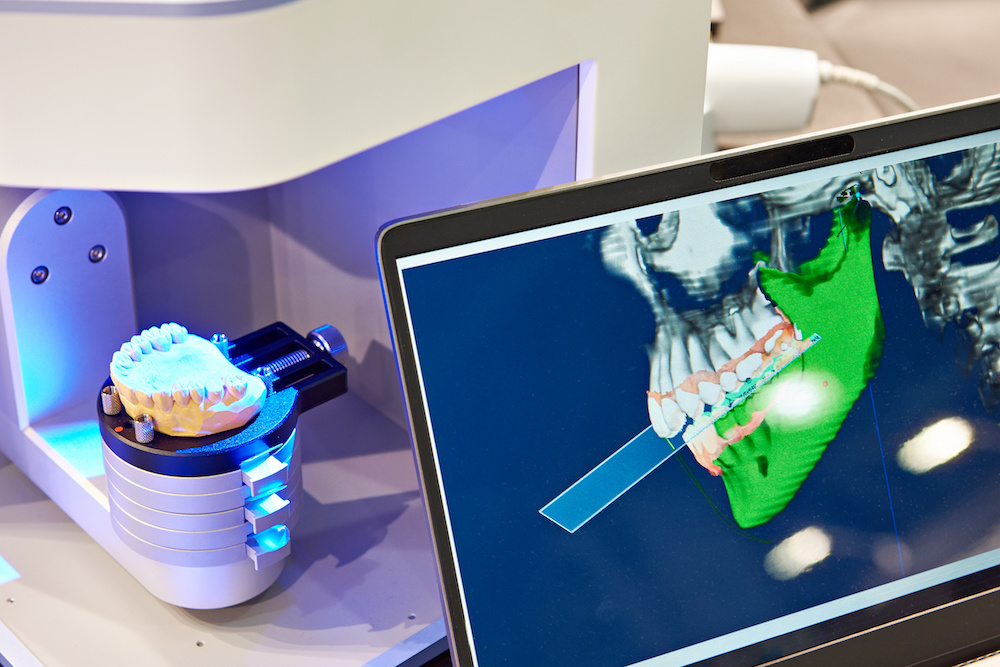

The capabilities of 3D printers continue to expand. Along with increased precision and speed comes exciting new use cases and innovative materials. EnvisionTEC 3D printers have the highest resolution of any 3D printers available today—down to .03mm of accuracy. The unprecedented precision supports part creation with little or no post-printing machining or processing, making them the choice for cutting edge companies and innovators in industries such as biofabrication, industrial manufacturing, medical devices, hearing aids, consumer goods, aerospace, automotive, entertainment, and others.

The materials you print with have just as much impact on the performance of a part as the method you use to print.

Want to explore other 3D printing materials? See what’s available with the MakerBot line.

Modern EnvisionTEC Materials

Many of these new use cases are enabled by the advances in EnvisionTEC materials. Here are some examples of materials that enable EnvisionTEC printers to lead the industry.

ABS EnvisionTEC Materials

- ABS Flex-White: Works well in snap-fit items because of its flexibility, yet it is tough enough for production-quality parts in automotive and consumer goods applications.

- ABS High Impact: Flexible yet strong, this material is ideal for any application requiring high speed builds, superior stress, force resistance, and surface quality.

E-Series EnvisionTEC Materials

- E-CE: Stiff and chemical- and heat-resistant, this material is great for industrial products needing thermal stability.

- E-Clear Series: Perfect for use cases that combine the need for a pleasing appearance with durability and heat and water resistance.

- E-Glass 2.0: A transparent material with an excellent surface finish for use in medical, optical, lighting, special effects, packaging, or art. It works well for end-use applications as well as prototypes.

- E-Poxy series: A tough, dual-cure material for strong, thin-walled products. It balances flexibility, hardness, and heat-resistance, making it a perfect choice for connectors and similar applications.

- E-Rigid PU: This material competes favorably with injection-molded plastic components. It is available in black, white, and natural, and has the strength, flexibility, and hardness, needed for a range use cases.

- E-RigidForm: Whether prototype or production, this resin prints strong, hard, stiff parts in amber, gray, or black. Its high tensile strength compares with acrylic, nylon 6, and carbonate. It has good heat deflection and water resistance characteristics.

- E-SHELL 200: A low viscosity liquid polymer for strong, water-resistant parts with high details. It is Class IIa biocompatible to ISO10993 and certified for use in hearing aids, otoplastics, and other medical devices.

- E-Shell 300: Designed specifically to meet the needs of the hearing aid industry, E-Shell 300 produces rigid yet durable parts It is available in multiple colors and transparent tones.

- E-Shell 3000: This liquid photo-reactive acrylate is CE certified and Class IIa biocompatible, making it ideal for hearing aid shells and otoplastics.

- E-Shell 500: Soft yet durable, this material is ideal for soft ear tips and shells. It is tough, water and perspiration resistant and available in clear or soft pink.

- E-Shell 600: Distinguished by its rigidity and durability, parts created with this material need little or no finishing and tolerate high-humidity environments well.

- E-Shore A: This polyurethane material produces items with soft Shore A values of 40 or 80, making it ideal for applications such as footwear, sporting goods, and other use cases where flexibility, durability, and comfort are paramount.

- E-Silicone: Used in eggshell/cocoon molds to custom fit hearing aids and medical devices to provide increased comfort, better retention, better acoustic seal, and improved sound quality.

- E-Tool 2.0: Filled with barium borosilicate glass, E-Tool 2.o is known for both heat and chemical resistance. It can deliver accurate tooling with an exceptionally smooth surface finish.

R-Series EnvisionTEC Materials

- R11: A liquid polymer for the accurate creation of functional parts with tolerance to ranges of temperature and humidity. Parts have superior fatigue properties, strong memory retention, and high-quality surface characteristics.

- R5: Ideal for parts that require superior chemical resistance or that must operate under extremes of temperature or humidity.

- R5-385: An update of R5, this material is optimized for 3D printers using 385nm wavelength light sources. The aerospace, entertainment, automotive, consumer and general manufacturing industries all use parts made with this material.

- RC-Series: Photosensitive resin infused with ceramic particles for use in wind tunnels, light reflectors, and automotive parts. The parts are tough but stiff and resistant to temperature extremes.

Other EnvisionTEC Materials

- HTM 140 V2: With its 1400 high deflection temperature, high definition parts can be directly vulcanized, eliminating the need for a metal master. It can also be used in applications that require high thermal resistance.

- LS600: Used in prototypes, end-use performance parts, snap-fit designs, impellers, ductwork, connector, and electronic covers, this material offers the best overall mechanical stability over time, even on highly detailed parts and parts that require temperature and moisture resistance.

- Photosilver: A ceramic filled photopolymer for highly detailed parts. Its high temperature-resistance enables the production of vulcanized molds with high definition and requiring minima post-print processing.

- PIC 100: Three times harder than carving wax, PIC 100 delivers stiff parts with exceptional surface finish, thin wall, and intricate details.

- Pro Gray: A liquid, photo-reactive resin for producing durable parts with high-quality surfaces. The parts have superior fatigue strength and tolerate a broad range of temperatures and humidity.

- Q-View: Ideal for the creation of custom pieces in a fast turnaround situation or silicone molds.

Of course, there is a whole other range of materials that can be used for biomedical 3D printing when working with the industry-leading EnvisionTEC Bioplotter.

EnvisionTEC Materials are Versatile and Adaptable

With such a wide range of materials, regardless of your 3D printing application, you are certain to find an EnvisionTEC material ideal for your purpose and your EnvisionTEC 3D printer. If you would like to learn more about the EnvisionTEC line of printers or the right material for your application, contact us today.