Additive manufacturing continues to make inroads deep into the prototype and production processes of progressive companies. As companies embrace 3D printing as the most efficient methodology for their processes, they are looking for more flexibility in the materials.

The recently-announced MakerBot Materials Program will help to solve this pressing need.

When it comes to creating innovative products with 3D printing, you can’t just consider what printing method you will use – you must also consider the materials you want to work with.

The MakerBot Materials Program

While the list of compatible MakerBot materials is already extensive, the METHOD Materials Development Program will rapidly increase the number of qualified materials. Working with its most progressive customers and partners, MakerBot will expand the filaments available, which will increase the potential applications for the MakerBot Method, Method X, and Replicator Z18.

MakerBot has introduced the MakerBot LABS Experimental extruder for use in certifying materials. This revolutionary extruder allows companies to tightly control advanced settings during the printing and qualification process for new materials. MakerBot is supplying the new extruders free of charge to a select few customers and partners to develop and certify new materials for use with MakerBot 3D printers.

MakerBot has introduced the MakerBot LABS Experimental extruder for use in certifying materials. This revolutionary extruder allows companies to tightly control advanced settings during the printing and qualification process for new materials. MakerBot is supplying the new extruders free of charge to a select few customers and partners to develop and certify new materials for use with MakerBot 3D printers.

The MakerBot Materials Program allows MakerBot users to find pre-qualified filaments, enabling 3D printing to become the technology of choice in many more applications and use cases.

3D Printing Materials Comparison of MakerBot Materials

The MakerBot Materials Program promises to keep the Method line of 3D printers at the forefront of the industry with the addition of revolutionary materials. In addition to these new materials, MakerBot already has an extensive line of options for a wide array of applications.

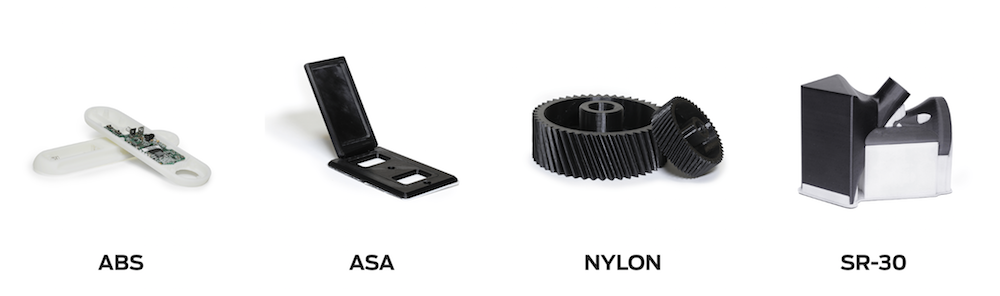

ABS

The Method X printer uses real ABS for molded consumer products. It’s durable, heat resistant, and has a clean, smooth finish. It’s an excellent choice for end-use parts, manufacturing tools, and functional prototypes. It provides good tensile strength and impact resistance and can deflect heat up to 2100 F. MakerBot ABS is available in multiple colors, including clear, and works with the 1XA and 2XA extruder.

ASA

Also compatible with Method X, and the 1XA and 2XA extruders, ASA is an excellent choice for outdoor applications because of its UV and moisture resistance. This MakerBot material is ideal for agricultural, transportation, and power and utility applications. It offers high tensile strength, heat deflection to 2040 F, and minimal elongation under strain.

Nylon

Suitable for use in both Method and Method X 3D printers, MakerBot nylon is used in production for automotive and industrial products and a wide variety of other industries for prototyping. Its characteristics make it ideal for applications where the part undergoes repetitive motions or must withstand applied force, such as gears, snap fits, articulated parts, hinges, and air intakes. MakerBot nylon is compatible with extruders 1 and 2.

Stratasys SR-30

Stratasys SR-30 is a proprietary dissolvable support material developed by Stratasys for use with high-temperature materials such as ABS, ASA, and others. It comes in clear and is compatible with both the Method and Method X. Using SR-30 enables you to create complex geometries with ABS, using extruder 1XA or 2XA.

PETG

Highly chemical resistant, PETG is useful in creating liquid containers or bottles. Chemical labs find it ideal for ensuring chemical resistance in parts and containers. PETG works well in end-use parts, manufacturing tools such as product testing fixtures, and in functional prototypes of protective guards, cooling tubes and custom machined parts. It’s available in three colors. PETG is compatible with Method or Method X using extruders 1 or 2.

PLA

Among the most office-friendly and eco-friendly materials, PLA is corn-based and is biodegradable when used in industrial processes. It comes in six colors and is compatible with Method, Method X, and Replicator Z18 printers equipped with extruder 1 or 2. PLA has a dimensional accuracy of 0.2mm, making it the ideal solution for precision applications.

Tough

Tough is easy to use and office-friendly as well as durable, pliable, and machinable. These characteristics make it perfect for prototyping snap fits and assemblies. It resists warping and curling and has twice the impact resistance of ABS. Tough is available in four colors and is works with Method, Method X, and Replicator Z18 printers equipped with extruder 1 or 2.

PVA

PVA is a water-soluble support material and is ideal for printing complex geometries during prototyping. It’s compatible with PLA, Tough, Nylon and PETG.

Build Innovative Products with MakerBot Materials

With the variety of MakerBot materials already available and the projections for innovative new materials arriving under the MakerBot Materials Program, an investment in a MakerBot 3D printer makes perfect sense. Whether you want to use it for prototyping or final production parts in a variety of applications and industries it can complete the tasks you need.

If you are interested in learning more about the industry-leading Method, Method X or Replicator Z18 3D printers and the MakerBot materials available, fill out the form below.

We’re happy to discuss all aspects of the equipment, the materials, and the MakerBot Materials Program with you.