IoT: Manufacturing and Design

McKinsey estimates that the IoT (Internet of Things) will have an economic impact of up to $11.1 trillion per year by 2025. They contend that 127 new devices connect to the Internet every second. That’s a lot of new devices, and the IoT is influencing product design in unexpected ways as companies strive to capture and use the resulting data.

IoT is a key component of Industry 4.0, the latest wave in the industrial revolution. Industry 4.0 incorporates technologies such as IoT, augmented reality, additive manufacturing, robotics, machine learning and artificial intelligence. Products in almost every industry are undergoing a digital transformation, and that has created a need for fundamental shifts in product design techniques.

Designing products for this new age requires a platform designed for the IoT so designers can provide the ability to connect and collect data. Connectivity is rapidly becoming the most important product feature of all, and augmented reality is becoming so mainstream it’s an integral part of the Windows operating system. It’s even in cell phone operating systems such as iOS.

But augmented reality is not just for gamers and party tricks. Augmented reality supports a capability known as a “Digital Twin.” A digital twin replicates the real time work environment to capture process anomalies to help prevent the creation of scrap or rework. As a result, product costs are lower. Throughput is maximized through the elimination or reduction of unplanned downtime and elimination of bottlenecks. On time deliveries increase, improving customer satisfaction and increasing revenue.

Digital twins can also predict how users will interact with products or new features to help designers understand the value and usability of their latest ideas. Seeing a user struggle to operate a product in augmented reality highlights design flaws better and faster than discussion-based focus groups can, and it helps speed up time to market. It can also prevent costly stumbles in the new product introduction cycle.

Traditional CAD and CAE products may not offer full support for IoT, AR and digital twinning. That’s why it pays to work with a company like PTC that has been in the vanguard of Industry 4.0 for years. For example, PTC introduced ThingWorx, a collection of essential tools and capabilities that support the new design paradigm.

PTC ThingWorx Overview

ThingWorx is an IoT platform that enables developers and designers to create and deploy smart, connected solutions that support the emerging technologies that comprise Industry 4.0. ThingWorx was built from scratch to simplify connection to IoT devices. It offers a complete set of development tools to enable creation of products that support a company’s digital transformation.

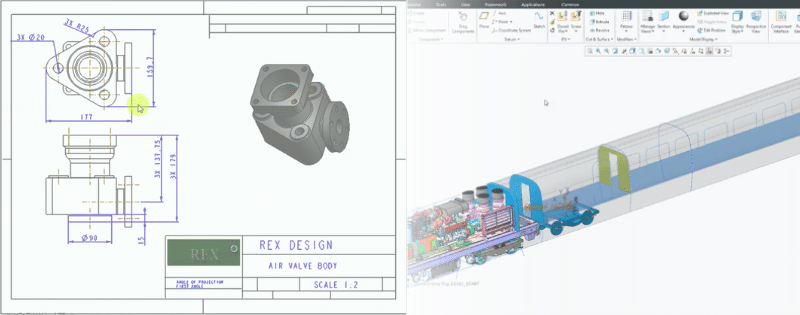

ThingWorx is able to integrate with Wildfire 4 and 5 to create AR images that can support that “wow” factor in design presentations and help ensure that products receive rapid acceptance. These three-dimensional digital twin images can be used to evaluate how customers use and respond to the product’s design.

ThingWorx is able to integrate with Wildfire 4 and 5 to create AR images that can support that “wow” factor in design presentations and help ensure that products receive rapid acceptance. These three-dimensional digital twin images can be used to evaluate how customers use and respond to the product’s design.

Using the AR and digital twin capability allows engineers to create the most efficient, error-proof production processes to help keep costs low once the product is released.

By creating a digital twin that replicates the real time manufacturing environment, ThingWorx helps keep existing processes on track and reduces or eliminates scrap or out-of-spec production that would require expensive rework. ThingWorx generates alerts for production interruptions or when production falls outside of acceptable parameters. It also monitors continuous connectivity, helping to prevent critical data loss. ThingWorx enables rapid, fact-based decisions based on real time data, helping to improve production and supply chain performance.

The ThingWorx platform offers easy extensibility so you can personalize the apps without affecting in-line code, allowing your company to enjoy the benefits of custom solutions along with the ease of upgrading “vanilla” systems.

Why PTC for IoT?

PTC is consistently named as a thought leader in IoT by such prestigious firms as Forrester, Gartner, and IDC. But PTC does more than think about the future; it creates and delivers tools that bring the future to today’s reality. In fact, PTC’s Senior VP Kevin O’Brien was featured at the IoT World Congress discussing the company’s ability to help its customers capture IoT and augmented reality opportunities.

Why 3HTi for IoT, AR and Industry 4.0?

3HTi is the largest PTC reseller on the East Coast and offers the full line of PTC products, including the ThingWorx IoT platform. We’ve been committed to customer success since our founding in 2002 and provide more than just software. We provide the consulting customers need to navigate the integration of complex IoT and PLM systems into their overall manufacturing and design processes and strategies.

3HTi is the largest PTC reseller on the East Coast and offers the full line of PTC products, including the ThingWorx IoT platform. We’ve been committed to customer success since our founding in 2002 and provide more than just software. We provide the consulting customers need to navigate the integration of complex IoT and PLM systems into their overall manufacturing and design processes and strategies.

If you’d like to learn more about how you can use ThingWorx to advance your Industry 4.0, digital twin and AR efforts… or just want to chat about the state of design and manufacturing enablement, contact us today.