Oil refineries break crude oil down into more usable material. It arrives via taker or pipeline, and is then pumped into large storage tanks. The crude oil then begins to undergo distillation as it is vaporized when heated by the system.

Heavier oils then move down to a fluid catalytic cracking unit (FCCU). The FCCU uses heat, pressure, and a catalyst to convert heavy fractions into components that can be used in asphalt, bunker oil, diesel, gasoline, heating oil, jet fuel, marine gas oil, and propane.

At the heart of the FCCU sits the cyclone. This equipment sorts the crude oil so that, when a mixed stream of catalyst and gas enters, the oil is thrust against the inside wall of the cyclone and moves into narrower and narrower sections.

Gas that separates from the catalyst exits from the top after flowing up through the cyclone’s center, while the catalyst spirals down the cyclone’s wall.

This complex process requires equally complex design work. Cyclones are massive pieces of equipment, weighing several hundred tons and requiring months of design. Engineers have to consider a number of factors, like:

- The number of cyclone stages

- The number of parallel cones

- Diameters

- Angles

- Lengths

- Wall thickness

- Materials

- Support systems

All of these factors have to be given careful consideration. And even the smallest mistake can be costly.

Cyclone design is a major concern for Jaraguá, a Brazilian company specializing in complete refinery design.

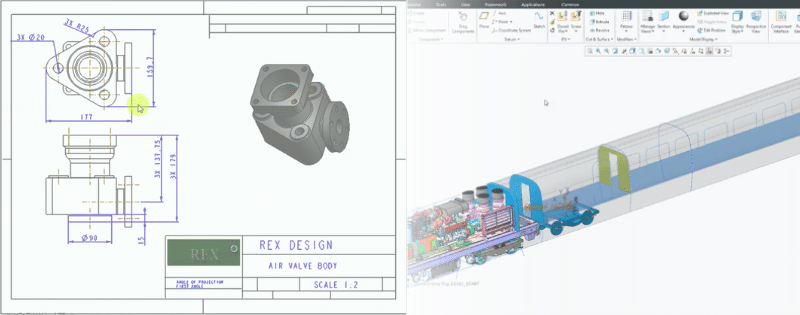

Jaraguá uses PTC Creo for 3D modeling and PTC Creo Advanced Assembly to work with large assemblies more effective. Using these tools helps them ensure their equipment is engineered with precision, without sacrificing a quick turnaround.

PTC Creo AAX makes data sharing, assembly configuration, top-down design, and assembly process planning simpler, allowing Jaraguá’s team to work on the model at the same time without risking the loss of changes. The team can also download simplified assemblies when they don’t require heavily detailed digital data. This accelerates system performance while still letting designers see their work within the framework of the larger design.

Thanks to PTC Creo AAX, Jaraguá can now design a cyclone within the overall skeleton of the whole oil refinery tower — in half the time it used to require. The company says that, thanks to PTC Creo, they’ve been able to reduce their design time by 40% and their errors by 605.

According to Daniel Maia, Jaraguá project coordinator, “With PTC Creo, we avoid rework, innovate solutions, and provide more detailed designs, resulting in less time in manufacturing and higher product quality.”

Interested in learning more about Creo and its 3D CAD capabilities? Read more about it here. Or why not contact us?