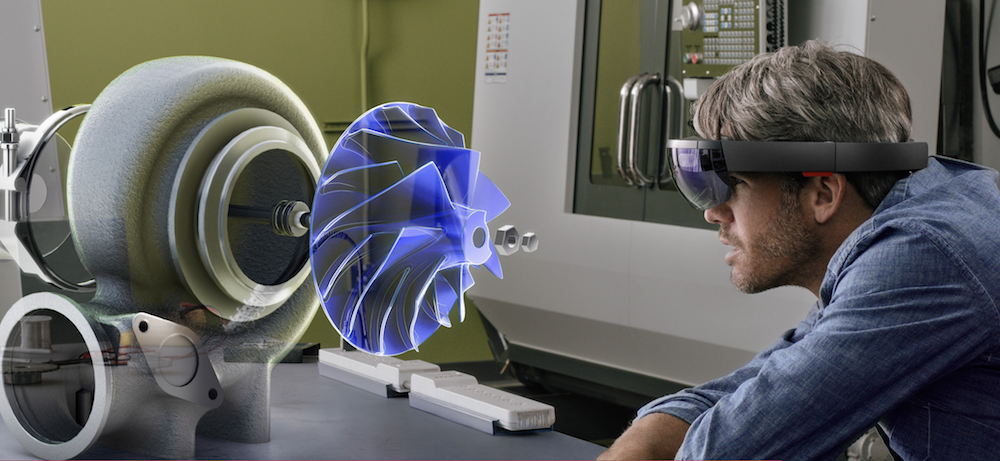

Augmented reality (AR) is a component of many digital transformation and industry 4.0 strategies. However, many organizations don’t understand the larger business benefits that AR can bring to manufacturing. As AR becomes more ubiquitous, businesses need to be prepared to implement this new technology to stay competitive.

Using AR for Manufacturing

AR is just one of the new technologies being implemented in the revolution of industry 4.0. It works alongside connected IoT, robotics, digital twins, VR, and more. While AR has captured the fascination of consumers, its ultimate use will be in manufacturing and industrial applications.

AR has captured the fascination of consumers – but its true impact will be felt across industrial applications.

Need help implementing your digital transformation strategy?

Benefits of Using AR for Manufacturing Operations

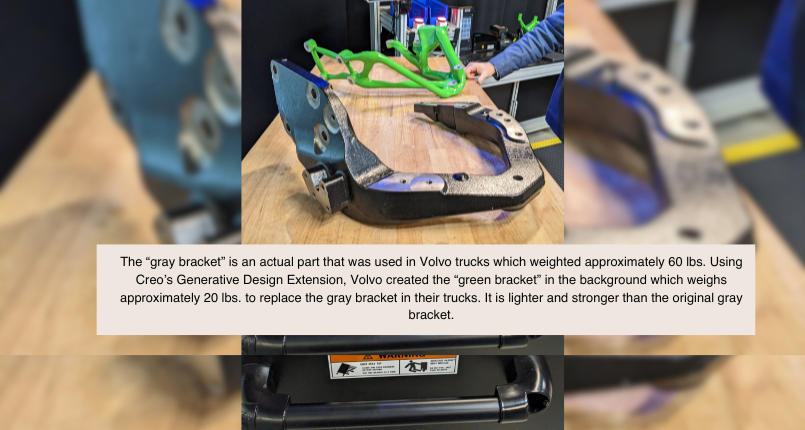

- Efficient prototyping: AR eliminates the need to create so many physical prototypes for products. Designers and engineers can use AR experiences to see exactly how products will look in the real world to make critical design decisions.

- Faster time to market: Similar to efficient prototyping, utilizing AR throughout the product development process allows decisions to be made faster. Having the ability to visualize products three-dimensionally and see how they appear in real-world environments makes it easier to make critical development decisions – regardless of where team members are located. Plus, these AR experiences and visuals can ultimately be used for product marketing and promotion without additional design work.

- Informative customer input: Organizations can use AR to observe how customers interact with products before final designs are set. Interacting with AR experiences instead of physical prototypes is faster, less expensive, and can be more accurate. This insight allows you to hit the market with the right feature set straight away instead of already planning the 2.0 version to include things you may have overlooked.

- Up-to-date manufacturing information: Traditional manufacturing operations rely on printed documents like routing sheets, assembly diagrams, and specifications to complete tasks. Unfortunately, this method means that instructions quickly become outdated. AR always has the latest information ready to go and can be deployed worldwide in a matter of minutes. Having these updates instantly helps to reduce manufacturing and assembly errors as well as scrap and operating time.

- Improved field support: Technicians no longer need to carry thick manuals or watch videos to figure out repair processes. AR combines the manual with instructions that link to the real-world conditions in front of them through a camera application to make repairs and upgrades faster and with more accuracy.

- Accurate training: The benefits of improved field support can also be felt across training programs. The time and costs of training a new technician or retraining an existing employee can be significantly reduced by using AR. Employees can spend just an hour or two working within an AR experience to simulate proper procedures and learn new techniques.

Vuforia Studio

There are plenty of benefits to using AR for manufacturing – but you need the right toolset to create these experiences. Vuforia Studio from PTC includes everything you need to implement AR across manufacturing operations. The platform covers AR needs across the entire development process from managing design through building and support as well as IoT connectivity.

Vuforia Studio includes the tools organizations need to create AR experiences to transform operations, facilitate knowledge transfer, and improve profitability.

Vuforia Studio Benefits

- Reduce development costs: Quickly create AR experiences in an intuitive authoring environment that utilizes and easy-to-use drag and drop interface with no coding experience required.

- Accelerate content creation: Create and reuse 3D CAD animated sequences to present products to key stakeholders or focus groups.

- Scale quickly: Access and deploy AR experiences across your organization using a single platform.

- Provide insight: Explore how users interact with products or analyze IoT data for actionable insights throughout the development process.

- Support workforce innovation: Create AR experiences that can be used for mixed reality and assisted reality.

Vuforia Studio and Creo: Better Together

Using Vuforia Studio with Creo allows organizations to truly unleash their potential for developing the products of tomorrow. Creo integrates seamlessly with Vuforia Studio so you can easily create AR experiences in a matter of minutes. Whether you are deploying AR in manufacturing for improved product development or better manufacturing operations, we recommend the combined power of Vuforia Studio and Creo for the most robust and integrated CAD solution.

Using Vuforia Studio with Creo allows organizations to truly unleash their potential for developing the products of tomorrow. Creo integrates seamlessly with Vuforia Studio so you can easily create AR experiences in a matter of minutes. Whether you are deploying AR in manufacturing for improved product development or better manufacturing operations, we recommend the combined power of Vuforia Studio and Creo for the most robust and integrated CAD solution.

Interested in learning how AR for manufacturing can be implemented in your organization? Looking for some guidance in implementing a digital transformation strategy?

Get a 30-minute consultation with a manufacturing expert.