As a designer, having all of the tools and capabilities you need in a single platform is critical. When it comes to modeling, all designers have their preference for direct or parametric modeling or choose to use both to perfect their visions.

Direct modeling allows designers to quickly define and capture geometry without the constraints of features or original design intent. In contrast, parametric modeling helps designers create shapes based on design intent, features, and constraints. Both have their pros and cons, but the best CAD software offers both in a single platform.

Direct modeling allows designers to quickly define and capture geometry without the constraints of features or original design intent. In contrast, parametric modeling helps designers create shapes based on design intent, features, and constraints. Both have their pros and cons, but the best CAD software offers both in a single platform.

In the current environment, only PTC Creo and Siemens NX CAD software offer both parametric and direct modeling, so the question is, which one is better?

Siemens NX vs. Creo: Feature Comparison

Just to be clear, we do resell Creo and think it is a great platform; however, we think there are pros and cons to both solutions and tried to remain unbiased in this analysis. Here are some of the main factors you should consider when selecting your CAD platform:

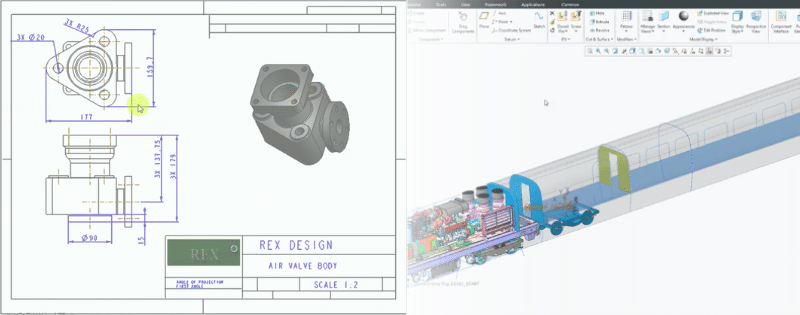

CAD Modeling

When it comes to 3D CAD modeling, both Creo and NX have some of the most advanced tools on the market compared to the competition. Unlike other options, they have both direct and parametric modeling capabilities. However, Siemens’ tools tend to be less intuitive and hard to use. The platform is great at what it does, but users comment on having a long learning curve to become proficient.

Creo and NX both offer comprehensive 3D CAD modeling capabilities – but Creo’s tools are easier to use.

Augmented Reality (AR), Internet of Things (IoT), and Additive Manufacturing

The digital environment is moving at a rapid pace, so designers and engineers need to be ready to start implementing the latest technology in their designs and to consider how those technologies will continue to evolve. In particular:

- Augmented reality (AR): AR is becoming an exciting component of product design. Engineers can utilize AR experiences to help show off their designs in real-world situations, work through iterations, and investigate potential problems.

- Internet of Things (IoT): Smart connected products are changing the manufacturing landscape. From tracking maintenance on machines to designing connected products, engineers need tools that can help them create the products of tomorrow.

- Additive manufacturing and 3D printing: This newer manufacturing method can be used to create end-use parts quickly or can be used to help cut development costs. Regardless, it requires a design process that is completely different from standard methods. Designers and engineers must consider how to build up rather than take away.

Creo includes the tools and features needed to design using these methods. The latest release of the platform, Creo 5.0 has advanced these tools even further. It has tools for creating and optimizing designs for 3D printing utilizing a wide range of materials, including metal. It also integrates with the ThingWorx Studio platform, which supports both IoT and AR designs. Lastly, improved AR capabilities with integrations into the Vuforia™ platform allow designers to create beautiful AR experiences in a matter of minutes.

Creo includes advanced design tools for augmented reality (AR), Internet of Things (IoT), and additive manufacturing.

In contrast, Siemens NX doesn’t include the extensive tools necessary to support these types of designs. Although the other design tools are comprehensive, the lack of tools for these newer technologies can lead to frustration for users as these capabilities become required in the future.

Integrations

The Siemens NX platform includes a few vendor-neutral exchange formats so users can share data in a multi-CAD environment. Users must use file format translators to share data, which is included in most (but not all) NX packages. The translators are easy to use regardless of file format, using familiar import and export menu functions.

Creo includes PTC’s revolutionary Unite Technology, which eliminates the need for time-consuming and error-prone file translations. Unite Technology allows Creo users to open files without any translations from a wide variety of platforms including SolidWorks, CATIA, and Siemens NX with Autodesk compatibility added in Creo 5.0. Having the ability to open all of these files simplifies collaboration and makes working in a multi-CAD environment a non-issue.

Creo includes PTC’s revolutionary Unite Technology, which eliminates the need for time-consuming and error-prone file translations. Unite Technology allows Creo users to open files without any translations from a wide variety of platforms including SolidWorks, CATIA, and Siemens NX with Autodesk compatibility added in Creo 5.0. Having the ability to open all of these files simplifies collaboration and makes working in a multi-CAD environment a non-issue.

Creo’s Unite Technology eliminates the need for file translations by allowing users to open CAD files from other systems directly within the Creo platform.

Collaboration

Design is no longer a siloed process completed exclusively by designers. Today, marketers, manufacturers, suppliers, and customers are all involved in the process, making streamlined collaboration a necessity. Creo includes secure sharing tools that make collaboration easy (especially in conjunction with Unite Technology). What’s more, it even includes simplified processes and menus for users who are not familiar with CAD.

Creo’s secure and easy-to-use sharing tools coupled with Unite Technology makes collaboration a breeze.

Siemens NX utilizes JT Data to share CAD information across platforms. It also integrates with the Siemens product life cycle management (PLM) platform Teamcenter to centralize all design notes, ideas, processes, and information. However, the cost of both of these systems can be in the millions and the platforms aren’t as streamlined and easy to use as the suite of options available in Creo.

Training and Support

The Creo platform includes a lot of resources. All Creo licenses come with access to over 200 online tutorials to help new and advanced users advance their skills. In addition, PTC has lively user communities supporting online, local, and regional groups that can be used as critical resources for users.

PTC also offers Smart Connected Support, which allows the Creo platform to report its own issues, search for solutions, and log incident reports – without impacting productivity or requiring any user input.

Siemens NX includes plenty of online support articles and user forums but doesn’t have anything that compares to PTC’s Smart Connected Support capabilities and doesn’t actually come with support at all. In addition, training can only be completed in person at the Detriot headquarters – so don’t forget to include that when budgeting for this solution.

Creo includes access to tons of online tutorials, plus Smart Connected Support ensures platform problems are fixed without impacting products.

Creo Is the Complete CAD Solution You Need

As we mentioned, we are a little biased towards Creo, but as you can see, it is for good reason. Creo has all of the tools and features you need to not only design products quickly, but also design the products of the future utilizing the latest and greatest technology.

We aren’t saying Siemens NX isn’t useful. We just find that our customers prefer the advanced capabilities that are available in Creo. Siemens is much more complicated and built for the aerospace and defense and automotive industries. If you work in one of these industries, Siemens may be the better choice, but keep in mind that it is not a common CAD tool and you will need to figure out how to integrate with the rest of your supply chain.

PTC Creo has all the tools and features your organization needs to design amazing products.

If you’re still unsure about Creo and want to know how it stacks up against other CAD solutions, check out our other article on PTC Creo vs. Autodesk Inventor.

Or if you have specific questions about Creo, feel free to contact us directly.