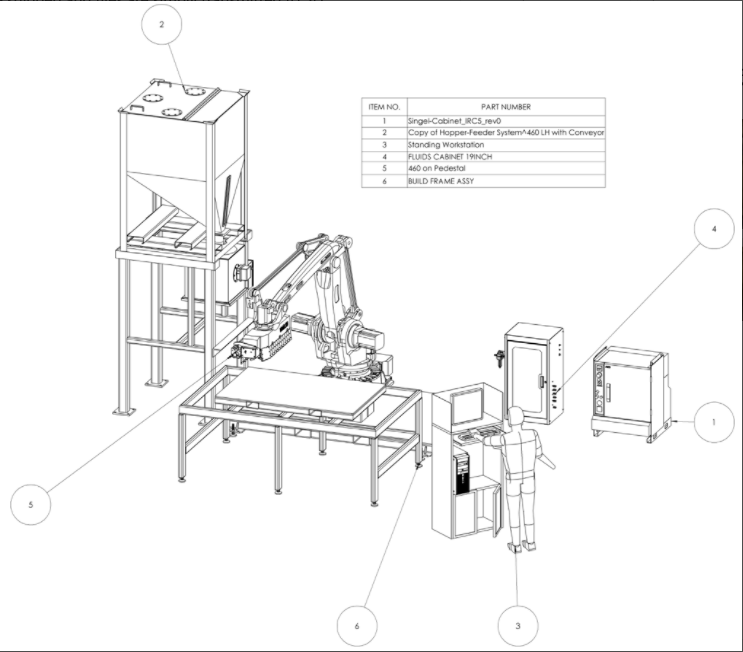

The EnvisionTEC Viridis 3D printer is an additive manufacturing system that utilizes Robotics Additive Manufacturing (RAM) technology to create custom castings in a matter of hours. The printer uses a proprietary print head attached to an ABB robotic arm to quickly create:

- Sand molds

- Mold cores

- Investment casting patterns

The EnvisionTEC Viridis 3D printer cuts down on the costs and time associated with creating castings compared to traditional methods. The printer is 1/3 the price of other print casting machines and complete part production time is reduced from 8-10 weeks to just 2-3 days.

The EnvisionTEC Viridis 3D Printer costs 66% LESS than other casting machines and allows foundries to begin producing custom parts in just 2-3 days.

Benefits

This custom casting 3D printer provides metal foundries with numerous benefits including:

- Fast printing: With a printing speed of 2.5 inches per hour, foundries can create new casts ready for part production use in just a few hours.

- Quick implementation: The entire printing system works out of the box. Once installed and calibrated, no further programming is required.

- Improved productivity: Foundry workers don’t need to be trained on new machinery as the solution utilizes other machinery they already use. And, since the solution is entirely automated after set up, operators don’t need to intervene during the printing process as the printer automatically cleans the printer head, parks, prints, and refills the sand chamber.

- Reduced material costs: RAM technology uses less sand than previous sand casting methods.

- Increased cast strength: Casts have incredible strength of 175psi when ambient dried and 370psi when baked at 350°.

- New production methods: Rather than having to create and ship casts around the world, organizations can simply ship the raw materials and transmit the casting files to their foundries for production.

How it Works

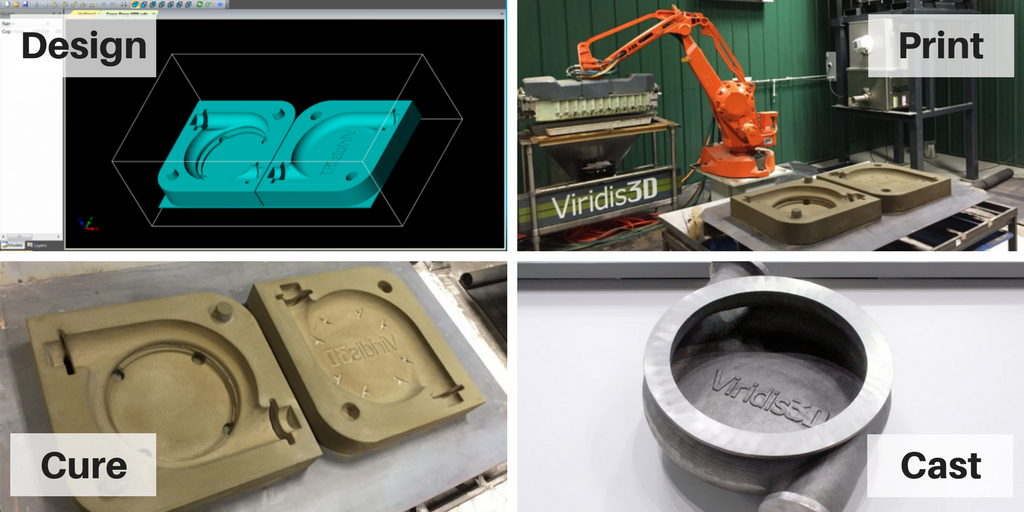

Software Process

- Launch and upload STL files into the Viriprint program.

- Users can set up, scale, orient, and justify the build volume of their print.

- Save print setup and orientation settings for easy repeat prints or to share settings with other foundries.

- Begin print job.

Printing Process

- Sandhopper delivery system fills the printer head from the backside with sand (solid consumable).

- ABB robotic arm positions the print head over the table.

- The Viridis 3D printing head drops, spreads, and prints the sand and binder jetting fluid.

- CAD software guides the arm, raising the height to complete the printing process layer by layer until the mold is complete.

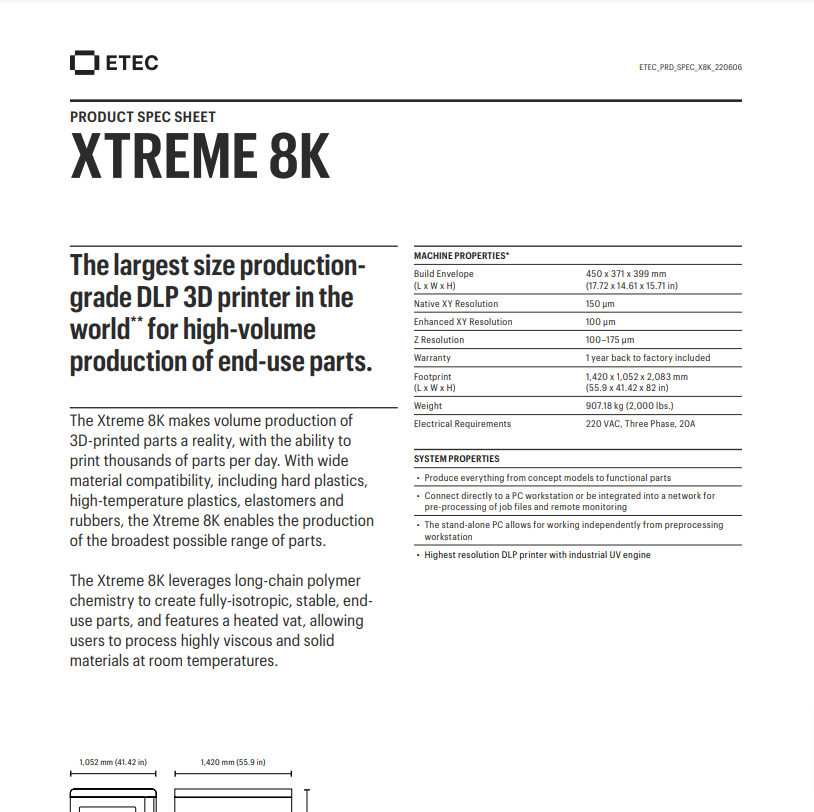

Technical Specs

- Print head and build size options

- 28” wide for 12 print heads

- RAM 123 (1’ x 2’ x 3’)

- RAM 224 (2’ x 2’ x 4’)

- 38” wide for 16 print heads

- RAM 236 (2’ x 3’ x 6’)

- RAM 336 (3’ x 3’ x 6’)

- 28” wide for 12 print heads

- Base sand options

- Silica sands

- GFN Oklahoma

- Wedron

- Additional sand options

- GFN65 round

- GFN65 subangular

- Binder: Modified Furan

- Catalyst: Premixed dry acid-based

- Layer

- Width: 200μ – 500μ

- Accuracy: +/- 0.010”

- Printing speed: 5 – 2.5 inches per hour

- Compatibility

- Ferrous sand casting

- Nonferrous sand casting

- Cast strength

- Ambient dry: 175psi

- Oven baked at 350°F: >370psi

Custom Casting with the EnvisionTEC Viridis 3D Printing System

Interested in learning more about the complete EnvisionTEC Viridis 3D printing system? Contact us.

Interested in learning more about the complete EnvisionTEC Viridis 3D printing system? Contact us.